News & Events / All EventsAdvanced Technologies and Tribology

Summer Short Course on Advanced Technologies and Tribology

June 18-21, 2024

Center for Surface Engineering and Tribology

Northwestern University, Evanston, IL 60208

Registration Fee: $3000

A tribological interface arises where parts come into contact and undergo relative motion. These interfaces entail five key components: materials, lubricants, surfaces featuring roughness and/or textures, surface functionalities, and operating conditions. Many of these components interact in various thermodynamic, tribophysical, and tribochemical states, influencing both themselves and the interfaces. Designing each aspect of these interfaces involves myriad choices and intricate details. For instance, selecting from a wide array of solid materials and coatings for surfaces subject to rubbing and other interactions requires careful consideration of many issues. The challenge lies in optimizing these five essential components to achieve specific goals in friction and wear control. In the age of artificial intelligence (AI), advanced technologies, such as data science and machine learning, are propelling tribology towards computational and data-driven surface-interface engineering. Concurrently, they facilitate deeper understanding of interfacial phenomena, paving the way for systematic product innovations in the future.

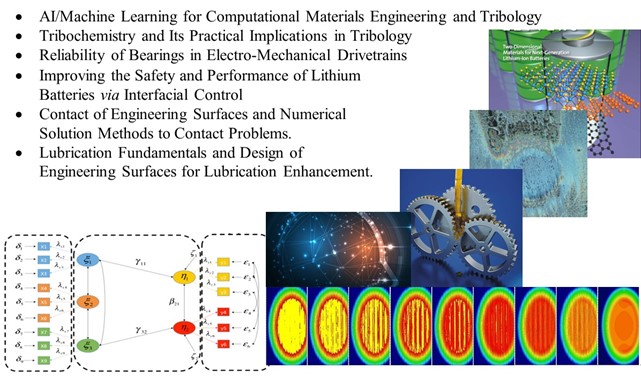

This short-course series endeavors to connect fundamental tribology with advanced surface-interface technologies and their industrial applications. Additionally, it aims to provide a structured pathway for future developments in tribology-related digital twins. The course series includes:

Meet the Instructors

Wei Chen: AI/Machine Learning for Computational Materals Engineering and Tribology

Course Content: AI/machine learning techniques are playing an increasingly important role in computational materials engineering including data-driven surface engineering. Building processing-structure-property relations is at the heart of computational materials engineering to accelerate materials and microstructural design. In this course, we will review the fundamentals of AI/machine learning techniques and their applications to data-driven materials engineering and tribology. Recent technological advancements on data acquisition, image-based microstructure characterization and reconstruction (MCR), machine learning of processing-structure-property relations, and inverse design will be introduced. Various MCR techniques will be reviewed followed by the introduction of feature selection and feature extraction techniques to identify the most significant morphological features for dimension reduction. This is then followed by introducing a wide range of statistical inference and machine learning techniques (e.g., Gaussian Process, Neural Networks and Deep Learning), applicable for either “small data” and “big data” problems. For inverse design, we will illustrate the benefits of Bayesian Optimization (BO) that enables human-in-the-loop adaptive learning with uncertainty quantification. The potential of deep-learning based generative design methods will also be described, demonstrated by microstructural and metamaterial design applications. Participants will gain hands-on experience of using computational algorithms such as Gaussian Process modeling and Bayesian Optimization.

wide range of statistical inference and machine learning techniques (e.g., Gaussian Process, Neural Networks and Deep Learning), applicable for either “small data” and “big data” problems. For inverse design, we will illustrate the benefits of Bayesian Optimization (BO) that enables human-in-the-loop adaptive learning with uncertainty quantification. The potential of deep-learning based generative design methods will also be described, demonstrated by microstructural and metamaterial design applications. Participants will gain hands-on experience of using computational algorithms such as Gaussian Process modeling and Bayesian Optimization.

Dr. Chen is the Wilson-Cook Professor in Engineering Design, Chair of Mechanical Engineering, Northwestern University, and a Member of the National Academy of Engineering (NAE) and American Academy of Art and Science (AAAS). Directing the Integrated DEsign Automation Laboratory (IDEAL-http://ideal.mech.northwestern.edu/), her research areas include simulation-based design under uncertainty; AI and machine learning for predictive science and engineering design; uncertainty quantification in multiscale analysis; data-driven design of heterogenous nano- and microstructural materials and programmable metamaterials; digital twins and design for advanced manufacturing; topology optimization; multidisciplinary design optimization; network analysis for modeling consumer preference and decision-based design. Dr. Chen is the recipient of the 2022 Engineering Science Medal from the Society of Engineering Science (SES), ASME Pi Tau Sigma Charles Russ Richards Memorial Award (2021), ASME Design Automation Award (2015), Intelligent Optimal Design Prize (2005), ASME Pi Tau Sigma Gold Medal achievement award (1998), and the NSF Faculty Career Award (1996). Dr. Chen served as the Editor-in-chief of the ASME Journal of Mechanical Design, the Chair of the ASME Design Engineering Division (DED), and the President of the International Society of Structural and Multidisciplinary Optimization (ISSMO). She received her Ph.D. from the Georgia Institute of Technology in 1995.

Yip Wah Chung: Tribochemistry and Its Practical Implications in Tribology

Course Content: Even under seemingly modest loads and speeds in typical tribological contacts, lubricant

molecules can experience significant shear stresses and elevated temperatures. These conditions have the potential to induce chemical transformations of the lubricant molecules. We'll start by providing a basic overview of these transformations before delving into scenarios where the contacting surfaces exhibit catalytic activity, influencing the pathways and kinetics of these chemical reactions. Some reactions may lead to lubricant degradation, while others may foster the formation of protective films that reduce friction and wear. Throughout the discussion, we'll illustrate with examples how tribochemistry plays a crucial role in mitigating friction and wear. This lecture aims to deepen participants' comprehension of the intricate relationship between chemistry and tribology, offering insights that could inspire innovative solutions to challenges across various engineering domains.

Dr. Chung is a Professor of Materials Science and Engineering and (by courtesy) Mechanical Engineering,  Northwestern University, Fellow of STLE, AVS, and ASM International, recipient of the Innovative ResearchAward from the ASME Tribology Division, the Technical Achievement Award from the National Storage Industry Consortium, and the 2024 AVS Ron F. Bunshah Award. His research areas include surface science, tribology, tribochemistry, design and characterization of lubricant additives, hard coatings, and high-performance alloys. In addition to his academic pursuits, Dr. Chung holds various FAA pilot and instructor certificates, including commercial multi-engine pilot and remote pilot ratings.

Northwestern University, Fellow of STLE, AVS, and ASM International, recipient of the Innovative ResearchAward from the ASME Tribology Division, the Technical Achievement Award from the National Storage Industry Consortium, and the 2024 AVS Ron F. Bunshah Award. His research areas include surface science, tribology, tribochemistry, design and characterization of lubricant additives, hard coatings, and high-performance alloys. In addition to his academic pursuits, Dr. Chung holds various FAA pilot and instructor certificates, including commercial multi-engine pilot and remote pilot ratings.

Aaron Greco: Reliability of Bearings in Electro-Mechanical Drivetrains

Course Content: Bearings in electro-mechanical drivetrains, such as wind turbines and electric vehicles, are often subjected to operational conditions that lead to premature failures and reliability issues. This includes the presence of stray electrical currents passing across the tribological contacts of these mechanical components. This course will examine the materials, lubricant, and operational factors leading to premature bearing failures including white-etching crack failures. Experimental evaluation using customized tribological test rigs have been used to replicate the operational conditions of these bearing components including the passage of controlled electrical currents. These experiments demonstrate that the passage of electrical currents can lead to surface and/or sub-surface material degradation that causes early life-limiting damage, depending on the lubrication condition of the contact.

Dr. Aaron Greco is a Principal Materials Scientist and Group Leader of the Interfacial Mechanics and Materials  Group at Argonne National Laboratory. He leads multiple DOE and industrial funded research programs on topics related to materials development for improved mechanical reliability, including a program to investigate material failures of wind turbine drivetrain components. Aaron’s technical background is in tribology, surface engineering, advanced manufacturing, and bearing reliability. He has published over 50 peer-reviewed journal articles and holds several patents. He serves as a Director on the Board for STLE and has received several awards including the Burt L. Newkirk Award from ASME Tribology Division and best paper awards from both STLE and ASME. Dr. Greco received his BS from Iowa State University and PhD from Northwestern University, both degrees in Mechanical Engineering.

Group at Argonne National Laboratory. He leads multiple DOE and industrial funded research programs on topics related to materials development for improved mechanical reliability, including a program to investigate material failures of wind turbine drivetrain components. Aaron’s technical background is in tribology, surface engineering, advanced manufacturing, and bearing reliability. He has published over 50 peer-reviewed journal articles and holds several patents. He serves as a Director on the Board for STLE and has received several awards including the Burt L. Newkirk Award from ASME Tribology Division and best paper awards from both STLE and ASME. Dr. Greco received his BS from Iowa State University and PhD from Northwestern University, both degrees in Mechanical Engineering.

Mark Hersam: Improving the Safety and Performance of Lithium Batteries via Interfacial Control

Course Content: Efficient energy storage systems represent a critical technology across many sectors including consumer electronics, electrified transportation, and a smart grid accommodating intermittent renewable energy sources. Arguably, the most important advance in energy storage over the past three decades is the lithium-ion battery, which was recognized with the Nobel Prize in Chemistry. However, despite its many successes, issues related to safety, energy density, charging time, and operating temperature range have hindered the realization of the full potential of lithium-ion battery technology, particularly in large-scale applications such as grid-level storage and full electrification of transportation networks. This course will explore how the aforementioned challenges for lithium-ion batteries are being addressed via interfacial engineering. For example, conformal graphene coatings on battery anode and cathode powders mitigate surface degradation and minimize the formation of the solid electrolyte interphase, thus improving cycling stability. In addition, the high electrical conductivity of graphene reduces cell impedance, resulting in enhanced kinetics that enable high-rate capability and low-temperature performance down to –20 °C. On the other hand, ionogel electrolytes based on ionic liquids and hexagonal boron nitride (hBN) nanoplatelets provide safe, high-rate operation at high temperatures up to 175 °C, which represents the highest operating temperature to date for solid-state lithium-ion batteries. The strong interfacial interactions between hBN and ionic liquids further enable novel electrolyte architectures based on layered heterostructure ionogels that result in unprecedently high energy densities and rate performance for solid-state batteries. Since hBN ionogels can be formulated into printable inks and slurries, these electrolytes also present promising opportunities for additive manufacturing of solid-state batteries, supercapacitors, and related energy storage technologies.

Dr. Hersam is the Walter P. Murphy Professor of Materials Science and Engineering, Director of the Materials  Research Center, and Chair of the Materials Science and Engineering Department at Northwestern University. He also holds faculty appointments in the Departments of Chemistry, Applied Physics, Medicine, and Electrical Engineering. He earned a B.S. in Electrical Engineering from the University of Illinois at Urbana-Champaign (UIUC) in 1996, M.Phil. in Physics from the University of Cambridge (UK) in 1997, and Ph.D. in Electrical Engineering from UIUC in 2000. His research interests include nanomaterials, additive manufacturing, nanoelectronics, scanning probe microscopy, renewable energy, and quantum information science. Dr. Hersam has received several honors including the Presidential Early Career Award for Scientists and Engineers, TMS Robert Lansing Hardy Award, AVS Peter Mark Award, MRS Outstanding Young Investigator, U.S. Science Envoy, MacArthur Fellowship, AVS Medard Welch Award, and eight Teacher of the Year Awards. An elected member of the National Academy of Engineering, American Academy of Art and Science (AAAS), Dr. Hersam has founded two companies, NanoIntegris and Volexion, which are commercial suppliers of nanoelectronic and battery materials, respectively. Dr. Hersam is a Fellow of MRS, ACS, AVS, APS, AAAS, SPIE, and IEEE, and also serves as an Executive Editor of ACS Nano.

Research Center, and Chair of the Materials Science and Engineering Department at Northwestern University. He also holds faculty appointments in the Departments of Chemistry, Applied Physics, Medicine, and Electrical Engineering. He earned a B.S. in Electrical Engineering from the University of Illinois at Urbana-Champaign (UIUC) in 1996, M.Phil. in Physics from the University of Cambridge (UK) in 1997, and Ph.D. in Electrical Engineering from UIUC in 2000. His research interests include nanomaterials, additive manufacturing, nanoelectronics, scanning probe microscopy, renewable energy, and quantum information science. Dr. Hersam has received several honors including the Presidential Early Career Award for Scientists and Engineers, TMS Robert Lansing Hardy Award, AVS Peter Mark Award, MRS Outstanding Young Investigator, U.S. Science Envoy, MacArthur Fellowship, AVS Medard Welch Award, and eight Teacher of the Year Awards. An elected member of the National Academy of Engineering, American Academy of Art and Science (AAAS), Dr. Hersam has founded two companies, NanoIntegris and Volexion, which are commercial suppliers of nanoelectronic and battery materials, respectively. Dr. Hersam is a Fellow of MRS, ACS, AVS, APS, AAAS, SPIE, and IEEE, and also serves as an Executive Editor of ACS Nano.

Jordan Liu: Contact of Engineering Surfaces and Numerical Solution Methods to Contact Problems

Course content. Digital twins bring rapid iterations and optimizations of product development /services. Numerical simulations of contact between engineering surfaces are indispensable to digital twins of tribological systems and are critical to the prediction of their performances under engineering situations. This session provides an in-depth understanding of the fundamental principles, advanced simulation techniques, and practical application related to contact mechanics, specifically focusing on the interaction between engineering surfaces and the numerical methods for simulating the behaviors of contacting surfaces. Concepts and theoretical foundations of contact mechanics will be introduced first, including classic theories and the analyses of deformations and stresses in various materials. Then, efficient numerical methods specially developed for solving rough-surface contact problems, such as the discrete convolution and fast Fourier transformation  method and the single loop conjugate gradient method, will be discussed. More FFT-based numerical methods for modeling contacts of other complicated engineering problems will be introduced. Participants will learn details and gain hands-on exercises on numerical contact modeling. This course will also introduce and demonstrate the newly developed Digital Tribology Lab (DiTL).

method and the single loop conjugate gradient method, will be discussed. More FFT-based numerical methods for modeling contacts of other complicated engineering problems will be introduced. Participants will learn details and gain hands-on exercises on numerical contact modeling. This course will also introduce and demonstrate the newly developed Digital Tribology Lab (DiTL).

Dr. Liu is a Research Professor in the Department of Mechanical Engineering, Northwestern University, Fellow oSTLE. He has over 15 years of industrial experience, both in research/development and product design/support at Caterpillar Inc. His research areas include contact mechanics, lubrication, frictional heat transfer, numerical solutions to tribological problems, and design of tribological components.

Jane Wang: Lubrication Fundamentals and Design of Engineering Surfaces for Lubrication Enhancement

Course content. Lubrication effectively reduces friction and wear, one of the most successful and robust means for energy efficiency in modern industries. However, lubrication design strongly relies on rheology of lubricants, properties of surface materials, and characteristics of surface topography. This course will start from fundamentals of lubrication, in terms of lubrication regimes of boundary, mixed, and full-film lubrications, typical lubrication behaviors in conformal and non-conformal interfaces, elastohydrodynamic lubrication (EHL), thermos- elastohydrodynamic lubrication (PEHL), and plasto-elastohydrodynamic lubrication (PEHL), as well as their relevance to running-in, wear, and scuffing. The emphasis will be given to mixed lubrication and related issues, principles of surface roughness selections for different industrial applications, and designs of surface textures and topography for lubrication enhancements, as well as construction for superlubricity. The course will also discuss the trend of future lubrication developments and recent advancements in lubrication theories. It will cover theoretical, numerical, and experimental works on lubrication, as well as case studies of related industrial applications.

Dr. Wang is the Joseph Cummings Professor in Mechanical Engineering, Executive Director of Center for surface Engineering and Tribology, Northwestern University, a Member of the National Academy of Engineering, and fellow of ASME and STLE. Research areas include mechanotribology, mechanics of solid-state batteries, multifield contact and interfacial mechanics, multifield lubrication, novel lubricants and lubrication technologies, and industrial applications of models, surface designs, and novel lubricants for friction reduction, lubrication enhancement, and failure prevention. Her research work has resulted in new theories, models and solution methods, and products for several tribological problems, interface simulation software for industrial applications, and surface roughness design principles for enhancement of lubrication of tribological components, which has also resulted in eight best-paper awards from ASME and STLE, the 2015 STLE International Award, the highest award of the society, and the 2024 ASME Mayo D. Hersey Award for her “distinguished and continued contributions over a substantial period of time to the advancement of the science and engineering of tribology.”

Engineering and Tribology, Northwestern University, a Member of the National Academy of Engineering, and fellow of ASME and STLE. Research areas include mechanotribology, mechanics of solid-state batteries, multifield contact and interfacial mechanics, multifield lubrication, novel lubricants and lubrication technologies, and industrial applications of models, surface designs, and novel lubricants for friction reduction, lubrication enhancement, and failure prevention. Her research work has resulted in new theories, models and solution methods, and products for several tribological problems, interface simulation software for industrial applications, and surface roughness design principles for enhancement of lubrication of tribological components, which has also resulted in eight best-paper awards from ASME and STLE, the 2015 STLE International Award, the highest award of the society, and the 2024 ASME Mayo D. Hersey Award for her “distinguished and continued contributions over a substantial period of time to the advancement of the science and engineering of tribology.”

Course Schedule

|

|

Tuesday June 18 |

Wednesday June 19 |

Thursday June 20 |

Friday June 21 |

|---|---|---|---|---|

|

8:30-10:00 am |

|

L2-1 (Chen) |

L4-1 (Wang) |

L6-1 (Hersam) |

|

10: 00 am |

|

Break |

Break |

Break |

|

10:30 am-12:00 pm |

Registration |

L2-2 (Chen) |

L4-2 (Wang) |

L6-2 (Wang) Closure (Wang) |

|

12:00-1:30 pm Lunch |

|

|

|

|

|

1:30-3:00pm |

Welcome/course overview (Wang) L1-1 (Liu) |

L3-1 (Chung) |

L5-1 (Greco) |

|

|

3:00 pm Break |

|

|

|

|

|

3:30-5:00 pm |

L1-2 (Liu) |

L3-2 (Chung) |

L5-2 (Greco) |

|

|

5:30 pm |

|

Welcome reception |

|

|

- L1: Contact of Engineering Surfaces and Numerical Solution Methods to Contact Problems.

- L1-1: Engineering Surfaces and Contacts

- L1-2: Contacts Simulations and Methods and Recent Developments

- L2: AI/Machine Learning for Computational Materials Engineering and Tribology.

- L2-1: Machine Learning (ML) Technologies

- L2-2: ML for Computational Materials Engineering and Tribology

- L3: Tribochemistry and Its Practical Implications in Tribology

- L3-1: Fundamentals of tribochemistry

- L3-2: Tribochemistry and Its Implications in Tribology

- L4: Lubrication Fundamentals and Design of Engineering Surfaces for Lubrication Enhancement

- L4-1: Lubrication Fundamentals and Advancements

- L4-2: Tribochemistry and Its Implications in Tribology

- L5: Reliability of Bearings in Electro-Mechanical Drivetrains.

- L5-1: Bearing Reliability Issues

- L5-2: Bearings in Electro-Mechanical Drivetrains

- L6: Improving the Safety and Performance of Lithium Batteries via Interfacial Control.

- L6-1: Safety and Performance of Lithium-Ion Batteries via Interfacial Control

- L6-2: Simulation of the Interfaces in Lithium-Metal Batteries