The Problem:

Gastrointestinal surgeries carry risk of fluid leaks, a potentially life-threatening complication.

Gastrointestinal surgeries carry risk of fluid leaks, a potentially life-threatening complication.

A new sticker changes in shape inside the body, enabling standard ultrasound technology to detect leaks for earlier detection and intervention.

Surgeon: "This new technology has potential to completely change the way we monitor patients after surgery"

John Rogers, Louis Simpson and Kimberly Querrey Professor of Materials Science and Engineering, Biomedical Engineering, and Neurological Surgery, et al.

Researchers led by Northwestern University and Washington University School of Medicine in St. Louis have developed a new, first-of-its-kind sticker that enables clinicians to monitor the health of patients’ organs and deep tissues with a simple ultrasound device.

When attached to an organ, the soft, tiny sticker changes in shape in response to the body’s changing pH levels, which can serve as an early warning sign for post-surgery complications such as anastomotic leaks. Clinicians then can view these shape changes in real time through ultrasound imaging.

Currently, no existing methods can reliably and non-invasively detect anastomotic leaks — a life-threatening condition that occurs when gastrointestinal fluids escape the digestive system. By revealing the leakage of these fluids with high sensitivity and high specificity, the non-invasive sticker can enable earlier interventions than previously possible. Then, when the patient has fully recovered, the biocompatible, bioresorbable sticker simply dissolves away — bypassing the need for surgical extraction.

The study will be published March 8 in the journal Science. The paper outlines evaluations across small and large animal models to validate three different types of stickers made of hydrogel materials tailored for the ability to detect anastomotic leaks from the stomach, the small intestine, and the pancreas.

“These leaks can arise from subtle perforations in the tissue, often as imperceptible gaps between two sides of a surgical incision,” said Northwestern Engineering’s John A. Rogers, who led device development with postdoctoral fellow Jiaqi Liu. “These types of defects cannot be seen directly with ultrasound imaging tools. They also escape detection by even the most sophisticated CT and MRI scans. We developed an engineering approach and a set of advanced materials to address this unmet need in patient monitoring. The technology has the potential to eliminate risks, reduce costs and expand accessibility to rapid, non-invasive assessments for improved patient outcomes.”

“Right now, there is no good way whatsoever to detect these kinds of leaks,” said gastrointestinal surgeon Chet Hammill, who led the clinical evaluation and animal model studies at Washington University with collaborator Matthew MacEwan, an assistant professor of neurosurgery. “The majority of operations in the abdomen — when you have to remove something and sew it back together — carry a risk of leaking. We can’t fully prevent those complications, but maybe we can catch them earlier to minimize harm. Even if we could detect a leak 24- or 48-hours earlier, we could catch complications before the patient becomes really sick. This new technology has potential to completely change the way we monitor patients after surgery.”

A bioelectronics pioneer, Rogers is the Louis Simpson and Kimberly Querrey Professor of Materials Science and Engineering, Biomedical Engineering, and Neurological Surgery, with appointments at the McCormick School of Engineering and Northwestern University Feinberg School of Medicine. He also directs the Querrey Simpson Institute for Bioelectronics. At the time of the research, Hammill was an associate professor of surgery at Washington University. Rogers, Hammill and MacEwan co-led the research with Heling Wang, an associate professor at Tsinghua University in Beijing.

All gastrointestinal surgeries carry the risk of anastomotic leaks. If the leak is not detected early enough, the patient has a 30 percent chance of spending up to six months in the hospital and a 20 percent chance of dying, according to Hammill. For patients recovering from pancreatic surgery, the risks are even higher. Hammill says a staggering 40-60 percent of patients suffer complications after pancreas-related surgeries.

The biggest problem is there’s no way to predict who will develop such complications. And, by the time the patient is experiencing symptoms, they already are incredibly ill.

“Patients might have some vague symptoms associated with the leak,” Hammill said. “But they have just gone through big surgery, so it’s hard to know if the symptoms are abnormal. If we can catch it early, then we can drain the fluid. If we catch it later, the patient can get sepsis and end up in the ICU. For patients with pancreatic cancer, they might only have six months to live as it is. Now, they are spending half that time in the hospital.”

In search of improved outcomes for his patients, Hammill contacted Rogers, whose laboratory specializes in developing engineering solutions to address health challenges. Rogers’ team had already developed a suite of bioresorbable electronic devices to serve as temporary implants, including dissolving pacemakers, nerve stimulators and implantable painkillers.

The bioresorbable systems piqued Hammill’s interest. The greatest odds of developing an anastomotic leak occur either three days or two weeks after surgery.

“We like to monitor patients for complications for about 30 days,” Hammill said. “Having a device that lasts a month and then disappears sounded ideal.”

Instead of developing new imaging systems, Rogers speculated that his team might be able to enhance current imaging methods — allowing them to “see” features that otherwise would be invisible. Ultrasound technology already has many advantages: it’s inexpensive, readily available, does not require cumbersome equipment and does not expose patients to radiation or other risks.

But, of course, there is a major drawback. Ultrasound technology — which uses sound waves to determine the position, shape, and structure of organs — cannot reliably differentiate between various bodily fluids. Blood and gastric fluid, for example, appear the same.

“The acoustic properties of the leaking fluids are very similar to those of naturally occurring biofluids and surrounding tissues,” Rogers said. “The clinical need, however, demands chemical specificity, beyond the scope of fundamental mechanisms that create contrast in ultrasound images.”

Ultimately, Rogers’ team devised an approach to overcome this limitation by using tiny sensor devices designed to be readable by ultrasound imaging. Specifically, they created a small, tissue-adhesive sticker out of a flexible, chemically responsive, soft hydrogel material. Then, they embedded tiny, paper-thin metal disks into the thin layers of this hydrogel. When the sticker encounters leaked fluids, it swells.

As the hydrogel swells in response to changing pH, the metal disks move apart. Then, the ultrasound can view these subtle changes in placement.

“Because the acoustic properties of the metal disks are much different than those of the surrounding tissue, they provide very strong contrast in ultrasound images,” Rogers said. “In this way, we can essentially ‘tag’ an organ for monitoring.” Because the need for monitoring extends only during a postsurgical recovery, Rogers team designed these stickers with bioresorbable materials. They simply disappear naturally and harmlessly in the body after they are no longer needed.

Computational collaborator Yonggang Huang, the Jan and Marcia Achenbach Professorship in Mechanical Engineering and professor of civil and environmental engineering at McCormick, used acoustic and mechanical simulation techniques to help guide optimized choices in materials and device layouts to ensure high visibility in ultrasound images, even for stickers located at deep positions within the body.

“CT and MRI scans just take a picture,” Hammill added. “The fluid might show up in a CT image, but there’s always fluid collections after surgery. We don’t know if it’s actually a leak or normal abdominal fluid. The information that we get from the new patch is much, much more valuable. If we can see that the pH is altered, then we know that something isn’t right.”

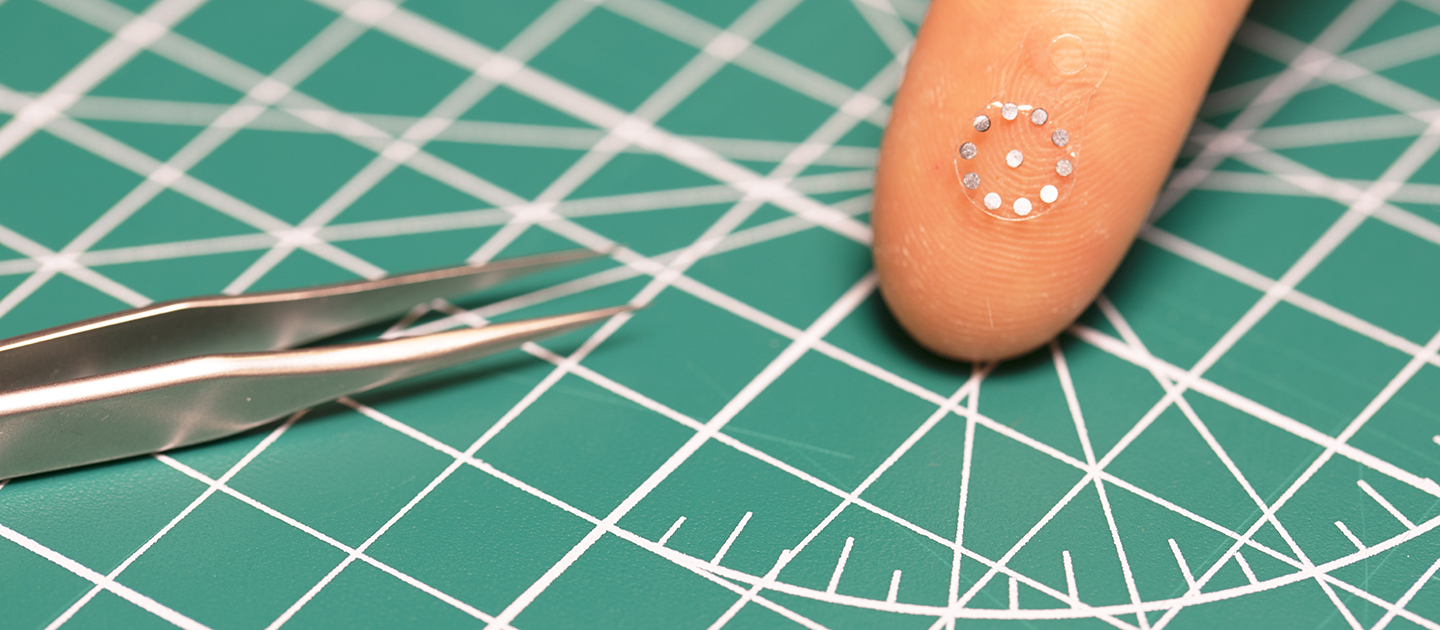

Rogers team constructed stickers of varying sizes. The largest measures 12 millimeters in diameter, while the smallest is just 4 millimeters in diameter. Considering that the metal disks are each 1 millimeter or smaller, Rogers realized that it might be difficult for radiologists to assess the images manually. To overcome this challenge, his team also developed software that can automatically analyze the images to detect with high accuracy any relative movement of the disks.

To evaluate the efficacy of the new sticker, Hammill’s team tested it in both small and large animal models. In the studies, ultrasound imaging consistently detected changes in the shape-shifting sticker — even when it was 10 centimeters deep inside of tissues. When exposed to fluids with abnormally high or low pH levels, the sticker altered its shape within minutes.

Rogers and Hammill imagine that the device could be implanted at the end of a surgical procedure. Or, because it’s small and flexible, the device also fits (rolled up) inside a syringe, which clinicians can use to inject the tag into the body.

“These tags are so small and thin and soft that surgeons can easily place collections of them at different locations,” Rogers said. “For example, if an incision extends by a few centimeters in length, an array of these tags can be placed along the length of the site to develop a map of pH for precisely locating the position of the leak.”

“It’s obviously an early prototype, but I can envision the final product where, at the end of surgery, you just place these little patches for monitoring,” Hammill said. “It does its job and then completely disappears. This could have a huge impact on patients, their recovery time and, ultimately, their quality of life.”

Next, Rogers and his team are exploring similar tags that could detect internal bleeding or temperature changes.

“Detecting changes in pH is a good starting point,” Rogers said. “But this platform can extend to other types of applications by use of hydrogels that respond to other changes in local chemistry, or to temperature, or other properties of clinical relevance.”