Novel Method Enables Enormous Datasets of Mechanical Properties in the Era of AI and Machine Learning

Technique enables rapid development of stronger and more robust adhesives

Adhesive materials are a key part our everyday life. Whether it’s in bioimplants, sealing incisions made during surgery, or cements for structural fastening, these materials are crucial throughout the engineering field.

New work from an interdisciplinary group of Northwestern Engineering researchers could make adhesive materials development quicker and more efficient.

Led by primary investigator Muzhou Wang, assistant professor of chemical and biological engineering at the McCormick School of Engineering, the team created a simple, inexpensive, and colorimetric characterization method for adhesive strength in soft materials that can run thousands of samples at the same time. The method can characterize a wide range of materials, including both synthetic and biomaterials, with the testing environment easily tuned.

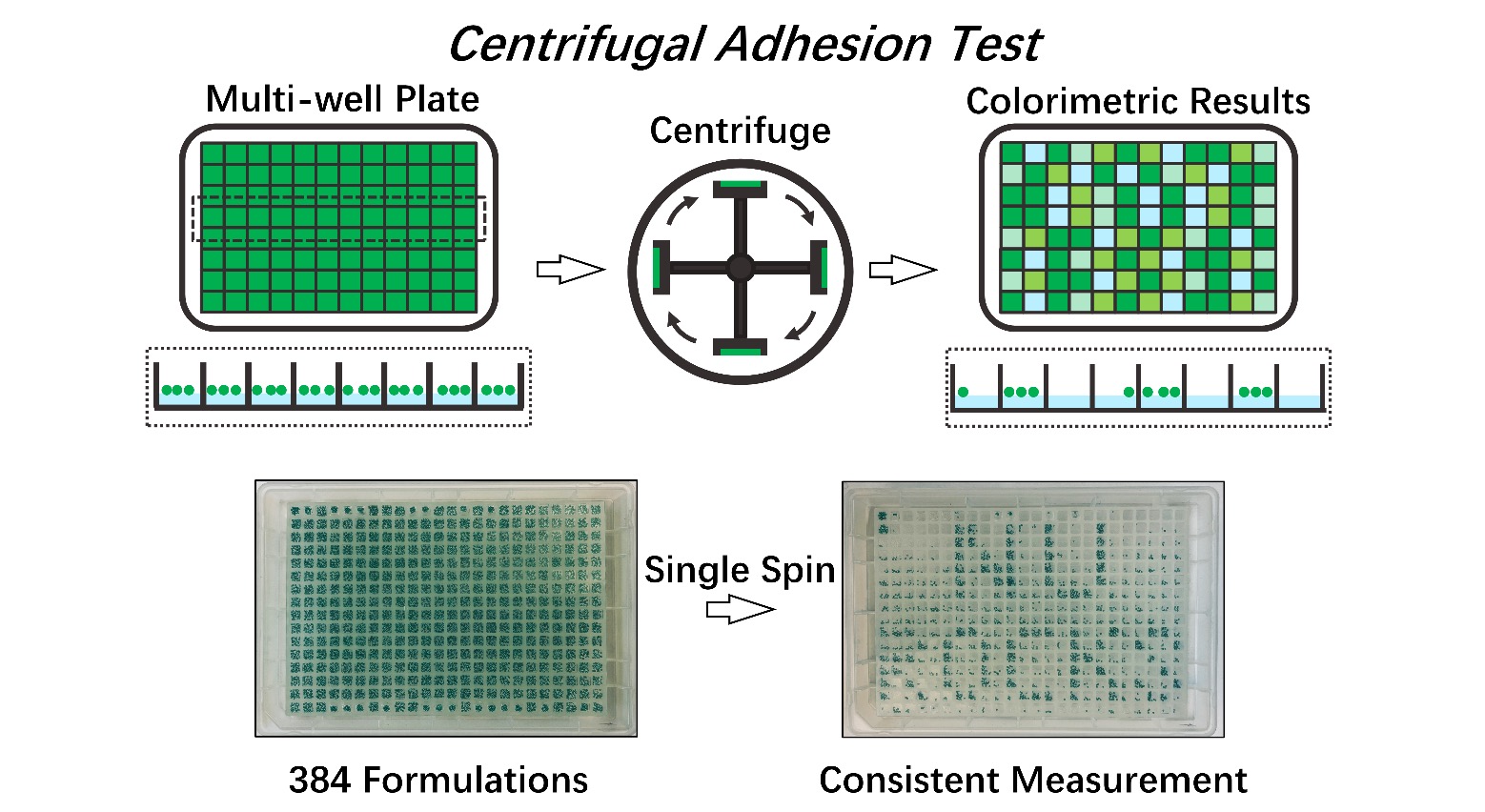

This method uses colored microparticles with centrifugation to apply a homogenous force across large arrays of samples. This enables massive sets of data on adhesive strengths, which in the era of machine learning, could result in custom-made formulation for various needs. Possible new materials could have exceptional properties that perform well under extreme environments, which would be discovered with the high-throughput characterization method devised by the researchers.

“This work is significant because traditional mechanical testing for materials can usually only characterize one sample at a time,” said Yusu Chen, the lead author of the paper and a co-advised graduate student with Wang and Danielle Tullman-Ercek, associate professor of chemical and biological engineering who also collaborated on the work. “Our method drastically shortens the amount of time required for the characterization process, both lowering the cost and improving the efficiency.”

Though machine learning is accelerating the development of many advances in science and engineering, its benefits are challenging to apply to materials science because characterizing materials can be a slow process. To use machine-learning tools in materials design, a large data set that correlates the chemical formulation of the materials to the material properties is required to train the models.

The research team’s method solves that issue.

“Our inexpensive and high-throughput screening method enables massive data collection for adhesive materials,” Wang said. “That opens the possibility of AI-designed materials in the future.”

Wang and his colleagues presented the research in the paper “High-Throughput Screening Test for Adhesion in Soft Materials Using Centrifugation,” published June 28 in the academic journal ACS Central Science. The paper is fully open-access.

The journal also produced a “First Reactions” article about the work.

This work was funded by a seed project from Northwestern’s Materials Research Science and Engineering Center (MRSEC), whose director is Mark Hersam, Walter P. Murphy Professor of Materials Science and Engineering and (by courtesy) electrical and computer

“This work embodies the interdisciplinary spirit of Northwestern Engineering and the Northwestern MRSEC,” Hersam said. “The realization of high throughput adhesive testing will have broad impact on the fields of materials science, mechanical engineering,

biotechnology, and beyond.”

Other collaborators included Kenneth Shull, professor of materials science and engineering, and additional members of the Shull and Tullman-Ercek groups.