Industrial Engineering Students Turn Organizational Data into Better Decision Making

Students worked with clients on open-ended problems across industries, including in education and healthcare

Every summer, Allyson Thorne, assistant principal at Attea Middle School in Glenview, Illinois, sits down to build the upcoming year’s schedules for the school’s 800 students.

Thorne spends hours poring over self-created Excel spreadsheets, manually ensuring that each student is assigned to their appropriate required courses, that classes meet necessary size and gender balance requirements, and that schedules are aligned with faculty breaks throughout the day.

The work takes her nearly four weeks to complete.

This summer, and many more after, setting the year’s schedules won’t feel as laborious, thanks to a student team in Northwestern Engineering’s Department of Industrial Engineering and Management Sciences. Using modeling and optimization techniques, the group developed the Attea Course Scheduler, with a user-friendly interface that automates the creation of individualized course schedules based on student and course data.

When implemented, the system will reduce the 160-hour process to produce every schedule to just 10 minutes.

The collaboration is a product of IEMS 394: IE Client Project Challenge, a one-quarter course that pairs industrial engineering juniors and seniors with organizations across a wide range of industries. Working with an IEMS faculty adviser, students are challenged to use their skills developed during earlier industrial engineering coursework to turn data from systems at sponsoring organizations into actionable insights that help solve an important problem.

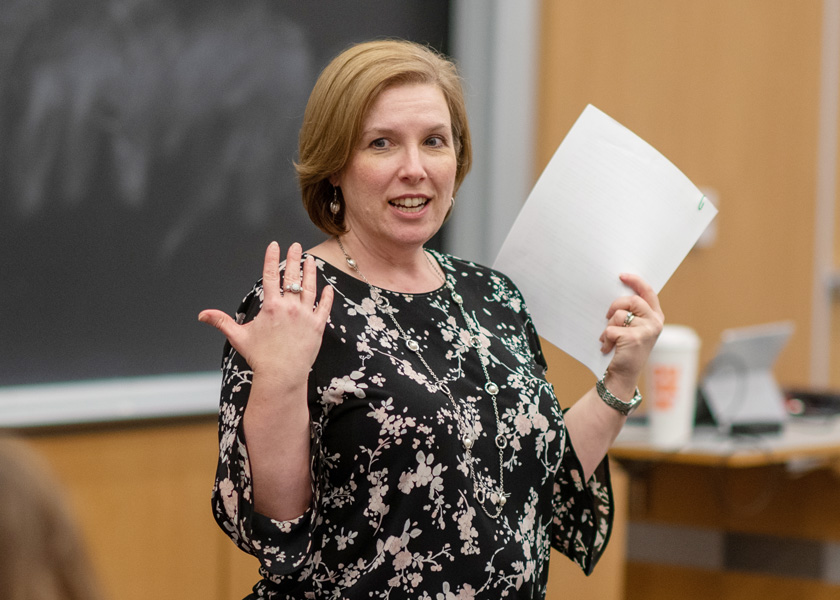

“Industrial engineering students are taught a lot about data analysis and computation and modeling, but at the end of the day, what they do is use that data to make decision recommendations,” said Jill Wilson, assistant chair and professor of instruction in industrial engineering and management sciences, who co-taught the course with Janice Mejia, associate professor of instruction in McCormick Undergraduate Engineering. “The course lets clients share real data with our students — even if it’s messy data — so students can leverage that data into tangible action.”

Streamlining school schedules

The five-student team collaborating with Attea Middle School spent weeks working with Thorne to understand the vast amount of data they needed to account for: three grades of students (sixth through eighth) each split into two different instructional teams, 17 different course subjects, and more than 100 different class options.

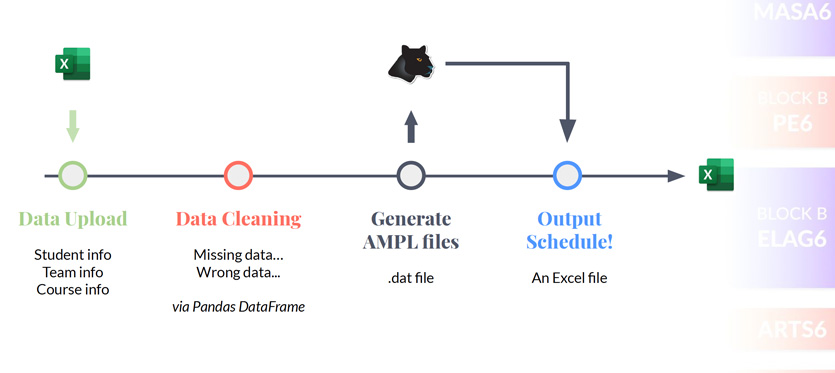

Using their shared experience taking courses focused on calculus, optimization, statistics, and simulation — skills the team dubbed their “IEMS Toolkit,” the group built the Attea Course Scheduler, a user-friendly service platform coded in Python that leverages an optimization model built in AMPL, a modeling language co-created by Robert Fourer, professor emeritus of industrial engineering and management sciences.

“We spent a lot of time thinking about how to use our industrial engineering skills, and we had experience using AMPL for optimization,” said group member Maya Zakarin, a rising senior. “It turned out to be the best fit. We could easily schedule one student for one class at one time while accounting for other needs.”

As industrial engineers, we have the skillset to create processes that make peoples’ lives easier.

Running the scheduler requires no coding skills. Intuitive controls — file upload buttons and dropdown menus — allow the scheduler to easily toggle between choices. The system also includes real-time error notification when it uncovers potential bugs in the data. The discrete optimization model implemented in AMPL accounts for the requirement that students should take only one course per subject and one course per time slot during the day.

“The Python program takes the three sets of data — student data, instructional team data, and course data — and creates a data file for AMPL,” said group member Caroline Christensen, a rising senior. “Our AMPL model then processes the data and uploads it back to the scheduler platform, which presents the data in an easy-to-read Excel file.”

Testing the model with sixth-grade data from Attea’s 2020-21 academic year, the group found their system produced individualized student course schedules with class sizes between 15 and 30 students and a nearly 50 percent male to female gender balance — all in less than 10 minutes.

“As industrial engineers, we have the skillset to create processes that make peoples’ lives easier,” Christensen said. “Not only were we able to optimize the process by which the student schedules are created, but we turned a 160-hour project into a 10-minute project. Our client now has much more time over the summer to work on other things.”

Attea Course Scheduler

Students per class

Balanced class sizes optimize the learning experienceMinutes

Platform produces 800 student schedules in minutesImproving nurse certification training

Another team collaborated with Medecipher Solutions, a software consulting company specializing in improving nurse retention, patient care, and clinical operations in hospitals.

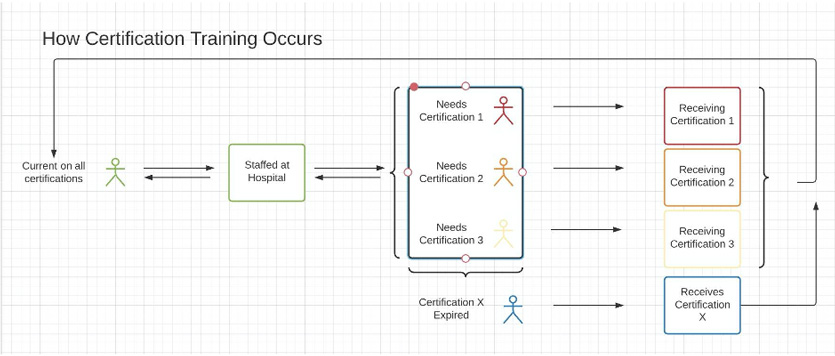

Co-founded by industrial engineering alum Stephanie Gravenor (’08, KSM ’16) and Sanjay Mehrotra, professor of industrial engineering and management sciences and director of the department’s Center for Engineering and Health, the company helps hospital administrators navigate the complexities of scheduling nurse certification training. In many hospitals, administrators work with nurses individually to sign up for training certification courses. Often, correspondence gets lost in email inboxes, creating stressful, last-minute registration, and increasing the likelihood a nurse will lapse in certification. Administrators also struggle to balance training events with ensuring hospitals are properly staffed with certified nurses.

Robert Norwood, a rising senior studying industrial engineering and economics, and his team developed a model that emphasizes central planning while accommodating individualized changes and preferences. Using AMPL to process the data and account for the system’s constraints, the model outputs a year-long schedule to Excel that spreads out nurse training during optimal periods throughout the year, maximizing the number of nurses available to work at a given time. Nurses can also request changes to their scheduled training, and the model can quickly rerun with the updated data.

“When each nurse is scheduling their own trainings individually, there’s no way to account for their preferences, and no way to ensure that there are as many nurses as possible available to work at a given time,” Norwood said. “This system provides Medecipher and their client hospitals a look at what a globally optimal solution looks like.”

Using simulated hospital data to test the model, the team found that the advanced notice that the system provides could help lead to fewer missed certification renewals, which would save both nurses and hospitals valuable time and resources.

Norwood said the course felt like a culmination of his work in the department.

“We weren’t just asked to write out a linear program,” Norwood said. “We used skills in economics, math, and computer science. As industrial engineering students, we understood how to combine these disciplines to create something that our client can use.”

Making a difference

Wilson said that Northwestern Engineering students are motivated to deliver value to clients while also addressing societal needs. That’s why some IE Client Project Challenge collaborations continue even after the class ends. Through a department fellowship supported by members of the IEMS Advisory Board, one industrial engineering student will work with Thorne this summer to further refine the Attea Course Scheduler and apply it to the upcoming school year’s data.

“This generation of students is much more interested in making global impact with their engineering work than just making more money,” said Wilson, Charles Deering McCormick Distinguished Professor of Instruction. “We can do more than make processes and systems more efficient. We can use our powers for good. This class facilitates those partnerships and allows our students to make a difference.”

Improving Decision Making Across Industries

Industrial engineering students in this spring’s IE Client Project Challenge course applied their skills to help solve problems in a variety of industries, from education to kitchen products to sporting goods – and even candy. Other projects included:

Denver Public Schools

Problem

Current bus routes transporting the school system’s approximately 45,000 riders is inefficient, containing multiple overlapping routes, resulting in students arriving to and leaving from school late.

Solution

The team created a linear programming model that eliminates bus stops less than a quarter mile apart. They also used Google’s OR-Tools optimization software to map out new, more streamlined routes between the updated stops while accounting for capacity constraints and travel times.

Ferrara Candy Company

Problem

The company’s seasonal mixed candy bags, which contain more than 100 different combinations of candies, are created according to minimum weight requirements without accounting for piece count, resulting in costly candy overfill.

Solution

Students created two optimization tools that allow the candy maker to select the desired mix of candy, handling weight and piece-count requirements for their mixed bag products. The tools also account for weight variability, reducing the risk of overfill and resulting in a potential 60 percent decrease in cost to produce the candy bags.

James Hardie Building Products

Problem

The building materials company, which manufactures and ships more than 10,000 SKUs, recently invested in its production capabilities, but quickly found their warehouses overcrowded, filled with lost or damaged products, and inefficiently using space.

Solution

Working with the company’s plant in Peru, Illinois, students analyzed the sales data and found that just 34 priority SKUs had the greatest impact on dwell time — how long a truck spends waiting at the warehouse. They formulated an optimization model designed to minimize forklift drive time by placing priority SKUs close to shipping lanes, and proposed new guidelines that will allow the plant’s shipping team to implement and maintain the new SKU assignment system.

JR286

Problem

The mid-sized sporting goods company has no mathematical and systematic method to determine the potential benefits of dynamically reallocating their labor force from its pool of full-time workers across its three warehouses.

Solution

Students produced a predictive model that forecasts labor needs based on unit and order demand. The system is flexible, offering daily, weekly, and monthly forecasting.

Pampered Chef

Problem

The kitchen and food products company employs a multi-level marketing structure with three different sub-groups of consumers, each with their own sales and promotions, making sales data difficult to understand and creating challenges in using that data to forecast future demand.

Solution

The team conducted an in-depth analysis of past sales data, emphasizing product-level demand and customers’ reactions to specific promotions. They also developed predictive analytics models to forecast demand for products purchased during special promotions.