Measurement Matters

With a focus on precision, Ping Guo unlocks opportunities for advanced manufacturing – and more

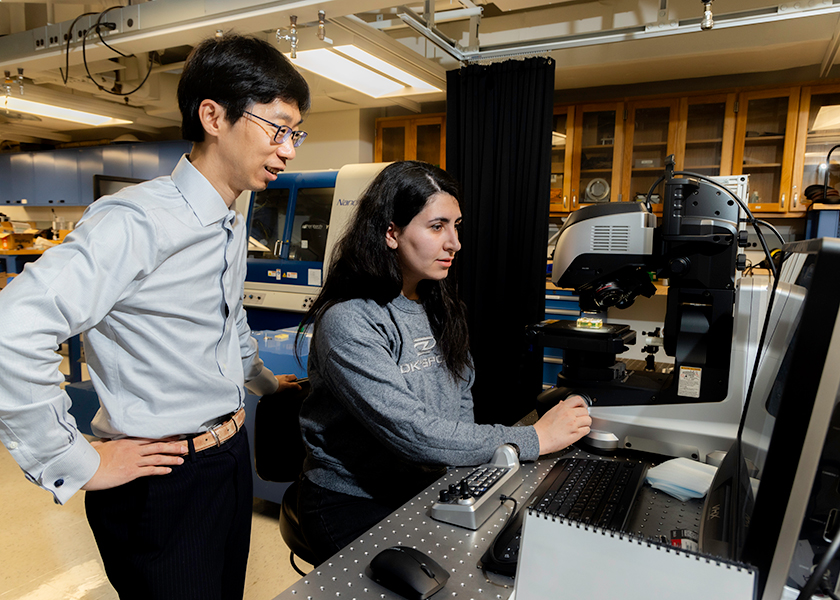

Northwestern Engineering associate professor Ping Guo insists his lab’s four-letter acronym – AIML – is pure coincidence.

When Guo joined Northwestern’s faculty ranks in 2018 and founded the Advanced Intelligent Manufacturing Lab, or AIML, he did not foresee incorporating artificial intelligence (AI) or machine learning (ML) into his work. Principally interested in pushing the limits of precision manufacturing, Guo has only recently mixed AI and ML into his innovative efforts to shape the future of manufacturing.

“That’s why I laugh about AIML today. It’s just by chance,” Guo said. “At the beginning, I was only thinking about precision. Everything else, the artificial intelligence and machine learning that’s very trendy today, comes later.”

But for Guo, progress elevates purpose and every successful step empowers grander scientific visions.

“I dream big for the next idea and try to make use of all the resources I have to realize it,” he said.

Born and raised in China, Ping made his first trip to the U.S. in 2009 to begin pursuing his PhD in mechanical engineering at Northwestern. Immediately, he appreciated Evanston’s small-town vibe paired with big city access. Even more, though, he relished Northwestern’s collaborative, interdisciplinary culture. Under one expansive roof at the 750,000-square foot Technological Institute, Guo could interact with engineers across multiple disciplines – mechanical, materials, and electrical among them – as well as computer scientists, applied mathematicians, and physicists. It fueled interesting conversations and bold ideas.

“Tech has such a lively environment that motivates great science,” he said.

During his PhD work, Guo helped create a novel way to pattern surfaces using elliptical vibrating cutting. He further developed this novel approach for structural coloration, which promised to unlock more precise manufacturing while also delivering long-term stability and sustainable production. While patents and published papers underscored the innovative nature of Guo’s work, limitations nevertheless remained. The surface’s interaction with light prevented efficient measurements.

“That’s where I realized I need to unlock the capability of measurement,” Guo said.

So, Guo cooked up an entirely different far-reaching idea for advanced manufacturing that relied on computer vision. Instead of a machine that needed to be calibrated or automated, as is commonplace today, what if cameras inside a room precisely controlled motion?

“You can only be as precise as you can measure,” he said.

Partnering with Northwestern colleagues from mechanical engineering and computer science, Guo began pursuing intelligent measurements, or computer vision metrology. Using a single set of inexpensive cameras, his team developed a way to do tracking, 3D reconstruction, and quality or surface inspection all in one – a once-unthinkable result. Guo’s spirited efforts have opened a door to faster, more precise, economical, and cost-efficient manufacturing in everything from traditional machine tools to the assembly of cars and robots.

The future is understanding, it’s intelligence. Not only measuring or seeing what’s going on in a space but understanding it.

“It’s more intelligent and more flexible,” Guo said. “Even though we’re doing scientific research, the bigger goal is trying to make an industrial impact.”

But Guo is far from done.

Most recently, he has turned his research attention to another science fiction-like chase utilizing computer vision metrology: spatial intelligence, or leveraging AI to understand, visualize, and process the 3D world. A technology able to comprehend an environment with speed and agility could have broad applications, from spotting defects in manufacturing to reconstructing a 3D environment so robots can efficiently and seamlessly operate within a defined space.

“The future is understanding, it’s intelligence,” he said. “Not only measuring or seeing what’s going on in a space but understanding it.”

And unlike his lab’s acronym, Guo assures that technology will be a byproduct of intentional, enterprising effort, not coincidence.