Making Material Advancements at the Nanoscale

The work emphasized the unique properties that nanoscale structures can exhibit compared to bulk materials

- Professors Horacio Espinosa and Chad Mirkin implemented a novel approach to design and assemble nanoscale materials using the principles that underpin colloidal crystal engineering with DNA.

- The researchers’ approach provides precise control over the arrangement of nanoparticles, enabling the creation of complex lattice structures with unnatural properties – in this case, high strength.

- The ability to engineer materials at the nanoscale with specific properties and architectures is a critical step toward "materials by design." This approach allows researchers to tailor materials for specific applications, offering a more efficient and effective way to develop new materials.

The nanoscale is quite small, but materials of this size significantly impact many fields, from electronics to aerospace to robotics to medicine.

In an interdisciplinary collaboration, Northwestern Engineering’s Horacio Espinosa and Chad Mirkin explored how nanoscale materials could be organized into macroscopic structures that exhibit properties that exceed those of conventional bulk materials and those exhibited by natural systems. They implemented a novel approach to design and assemble nanoscale materials using colloidal crystal engineering with DNA, a methodology developed by Mirkin over the past three decades. This approach provides precise control over the arrangement of nanoparticles, enabling the creation of complex lattice structures.

“The ability to engineer materials at the nanoscale with specific properties and architectures is a critical step toward ‘materials by design,’” Espinosa said. “This approach allows researchers to tailor materials, in this case high-strength ones, for specific applications, offering a more efficient and effective way to develop new materials."

A paper describing the work, titled “Ultrastrong Colloidal Crystal Metamaterials Engineered with DNA,” was published September 29 in the journal Science Advances. Espinosa and Mirkin are the paper’s co-corresponding authors.

Espinosa is the James N. and Nancy J. Farley Professor in Manufacturing and Entrepreneurship and Professor of Mechanical Engineering at the McCormick School of Engineering. Mirkin is the George B. Rathmann Professor of Chemistry in the Weinberg College of Arts and Sciences, professor of medicine at Northwestern University Feinberg School of Medicine, and professor of chemical and biological engineering, biomedical engineering, and materials science and engineering at Northwestern Engineering.

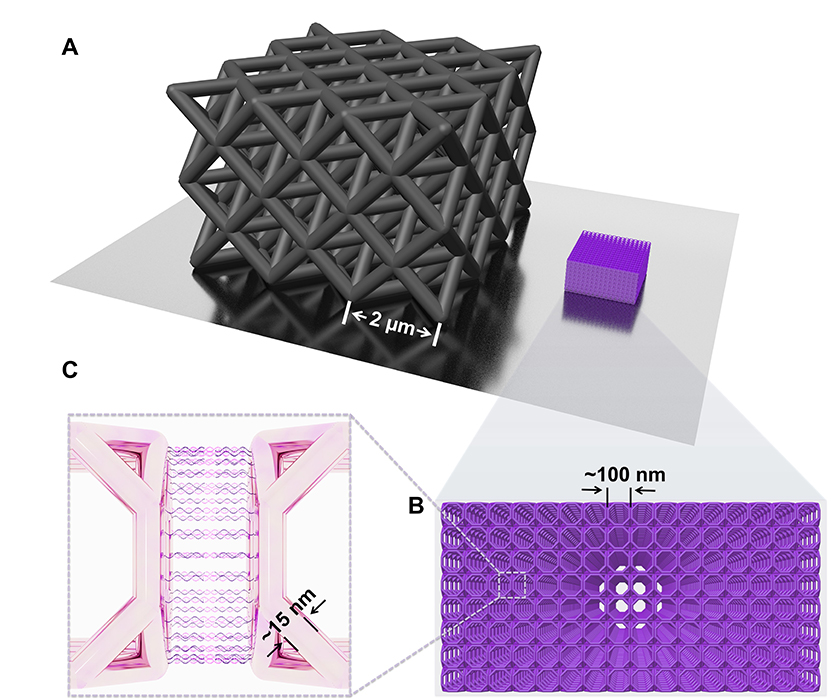

As part of their approach, the researchers designed particle-DNA constructs that favored specific interactions between nanoparticles – such as edge-to-edge or facet-to-facet. This design allowed them to assemble simple cubic lattices from these functionalized nanoparticles. After lattice assembly, the crystal structures were stabilized with silver ions. The structures’ mechanical responses were tested using in-situ scanning electron microscopy compression.

“These experiments and tests provided comprehensive data on the mechanical properties, deformation mechanisms, and structural characteristics of the assembled nanoscale lattices,” Mirkin said. “The results are non-intuitive and show how one creates materials with exotic properties by combining the appropriate nanoscale building blocks and DNA sequences. We are learning how to repurpose the blueprint of life and direct it towards a long-standing challenge in materials science - materials by design.”

The researchers found that while the three lattices tested were designed with identical crystal symmetries, the particle building blocks used in each material— nanoframes, nanosolids, and nanocages — produced different material stiffnesses and strengths. The lattice created from nanoframes was approximately five times stronger than those made from nanosolids and nanocages.

“Our findings showcase the potential of colloidal crystal engineering with DNA as a versatile method for creating a wide range of mechanical metamaterials,” Espinosa said. “These nanoscale metamaterials exhibit reduced sensitivity to imperfections, which is a crucial characteristic for practical applications.”

Those applications could include the environment, as lighter and stronger materials in transportation can lead to fuel savings and reduced emissions. Another is innovation in materials that power many of the electronics we use daily.

“Breakthroughs in this field often lead to advances in consumer products, electronics, transportation, robotics, aerospace, and medical devices,” Espinosa said. “This research paves the way for the development of stronger and lighter materials that can impact many everyday technologies.”

The work was funded by the Air Force Office of Scientific Research awards FA9550-22-1-0300 (crystal synthesis), FA9550-20-1-0258 (mechanics of metamaterials), ONR award N00014-22-1-2133 (computational modeling) and the Center for Bio-Inspired Energy Science, an Energy Frontier Research Center funded by the US. Department of Energy, Office of Science, Basic Energy Sciences award DE-SC0000989 (SEM and TEM characterization).