Redesigning Materials Design

The Northwestern-led Center for Hierarchical Materials Design builds a revolution focused on how engineers worldwide create new materials.

"CHiMaD is broadening the materials design strategy from metals to just about every materials class you can imagine.”

About 30 years ago, after his daughter was born, Greg Olson moved from being a research scientist at MIT to becoming a faculty member at Northwestern Engineering’s Department of Materials Science. Fatherhood had inspired him to make the world a better place.

“As a scientist, you take things of known technological value and try to understand how they work. But I wanted to engineer solutions instead,” he says.

With that motivation firmly intact, Olson, Walter P. Murphy Professor of Materials Science and Engineering, now serves as one of three codirectors of the Northwestern-led Center for Hierarchical Materials Design. Known as CHiMaD, the center is a collaboration among 53 principal investigators at eight institutions with the “humble” aim of revolutionizing the way the world designs new materials.

“CHiMaD is broadening the materials design strategy from metals to just about every materials class you can imagine,” says Peter Voorhees, codirector and managing director of CHiMaD and Frank C. Engelhart Professor of Materials Science and Engineering at the McCormick School of Engineering.

The Vision

Launched five years ago through a $25 million award from the National Institute of Standards and Technology (NIST), CHiMaD is tasked with developing databases, computational tools, and experimental techniques to drastically decrease the time and expense of discovering and commercializing novel materials. Already, the center’s work has led to the creation of new, high-performance materials for everything from computers to space travel. In January 2019, NIST renewed CHiMaD’s funding to fuel another five years of advances, which fit within the vision of a larger national project called the Materials Genome Initiative.

Olson notes, “Just as DNA acts as a database that directs the assembly of living things, we’re building databases of the parameters that direct the assembly of nonliving things. Together with computer programs that analyze them, these databases take much of the guesswork out of the process of mixing substances to create new ones with specific properties, like strength.

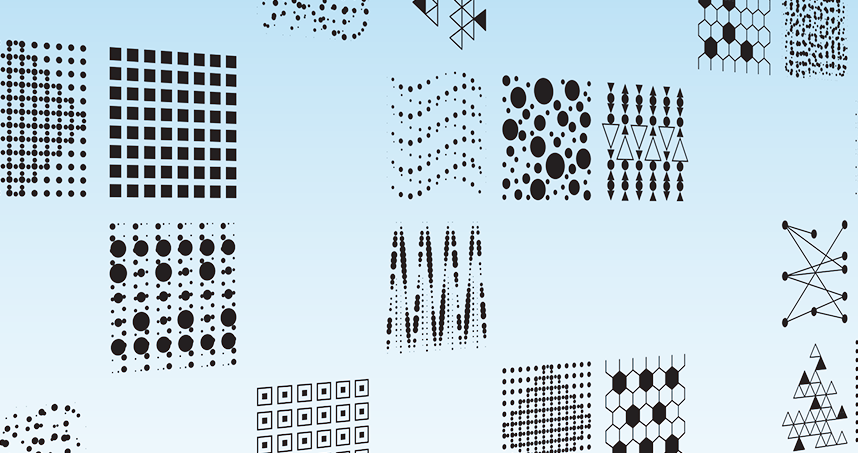

“All materials are intrinsically hierarchical because their structures can be analyzed on multiple length scales,” Olson continues. “To design them, we have to address all those scales, starting with their quantum interactions.”

Idea to Market

Iteration is key to the process. The engineers begin with a list of desired characteristics, then build a computer program to search for them in a dataset of theoretical or experimental data. They use the program’s predictions to make a few materials in the lab, and then test their properties, sometimes with highly specialized equipment, like the advanced photon source that Voorhees uses at Argonne National Laboratory, another CHiMaD partner. With more accurate data and some machine learning, the algorithms’ predictions improve with each round of the process.

Once a new material is discovered, engineers still have much work remaining to get it to market. This is where industry partners, like QuesTek Innovations, cofounded by Olson in 1996, come into play. In collaboration with CHiMaD, the company is now applying its computational tools to the field of 3D-printed metals, even for objects as large as naval ship propellers. Meanwhile, Mark Hersam, Walter P. Murphy Professor of Materials Science and Engineering, is printing atomically precise 2D electronic materials, which are already being distributed by MilliporeSigma.

From Metals to Polymers and Beyond

Another CHiMaD innovation to reach industry comes from Juan de Pablo, the third codirector of CHiMaD and the Liew Family Professor in Molecular Engineering at the University of Chicago, a partner institution. His wheelhouse is organic polymers — large, carbon-containing molecular chains or networks made up of smaller, repeated units.

“Databases and design methods for metals have been worked on for decades,” he says, “but we are just beginning to develop them for polymers and softer materials.” His computational tools for predicting the self-assembly of special polymers into nanometer-thick “wires” are already being used by the semiconductor industry to design microchips.

Thermoelectrics is the focus of another ongoing project at CHiMaD. The project is led by G. Jeffrey Snyder, professor of materials science and engineering, in collaboration with Chris Wolverton, Jerome B. Cohen Professor of Materials Science and Engineering, who brings expertise in machine learning. The two are searching for optimal materials to solve one of the world’s most challenging energy problems: how to harness the approximately two-thirds of the world’s energy use that’s wasted as heat. While some existing thermoelectric materials have the potential to do that by generating electricity, they’re too inefficient to be cost effective.

“This is exactly the kind of problem for CHiMaD to tackle,” Wolverton says. “We’re all about accelerating the discovery process.”

The computational tools and data the CHiMaD collaborators are creating hold the long-term promise of truly revolutionizing new materials design worldwide and making the world a better place. As Voorhees says, “The impact will be felt for generations.”