Improving MRAM by Lessening Reliance on Electric Currents

A new material could allow memory devices to get smaller and more energy-efficient

Microelectronic chips are tiny, but producing enough of them to satisfy their growing demand in our lives has proven to be a big challenge. During the recent semiconductor chip shortage that disrupted global supply chains, myriad products ranging from cars to video game consoles became costlier and more difficult to acquire. The shortage led Congress to pass the CHIPS and Science Act, which aims to fund up to $280 billion of semiconductor chip production, research, and development in the United States.

Northwestern Engineering’s Pedram Khalili is aware of these issues, and recent work by he and his team could help tackle key obstacles to future semiconductor chip availability.

In the paper “Sub-Volt Switching of Nanoscale Voltage-Controlled Perpendicular Magnetic Tunnel Junctions”published November 14 in the journal Communications Materials, Khalili addresses two areas where existing semiconductor solutions are facing major challenges: density (bits-per-area) and energy efficiency (energy-per-operation).

A key emerging memory technology that could potentially address this need is magnetic random-access memory (MRAM), which has a combination of speed, endurance, and nonvolatile operation that makes it an attractive alternative compared to both existing and other emerging memories. Khalili’s group has been active in developing materials and devices for MRAM, but is also aware of its limitations. Controlled by electric currents, the present version is fundamentally limited in how small its energy-per-operation can be, and how closely bits can be placed together —surrounding transistors must be large enough to provide those electric currents.

This technology can allow MRAM to scale to much higher densities, thereby addressing a wide range of applications such as artificial intelligence accelerator chips, graphics processing units, and other types of computing hardware.

Pedram KhaliliAssociate Professor of Electrical and Computer Engineering

Khalili and his team have developed an alternative voltage-controlled MRAM (VCM) technology that does not rely on electric currents to switch the magnetic memory bits.

“This technology can allow MRAM to scale to much higher densities, thereby addressing a wide range of applications such as artificial intelligence accelerator chips, graphics processing units, and other types of computing hardware,” said Khalili, associate professor of electrical and computer engineering at the McCormick School of Engineering.

VCM technology, however, is a work in progress. It requires high switching voltage: all VCM devices demonstrated to date needed around two volts or more to switch, which is too high for integrated computing chips, which usually have transistors operating at less than one volt.

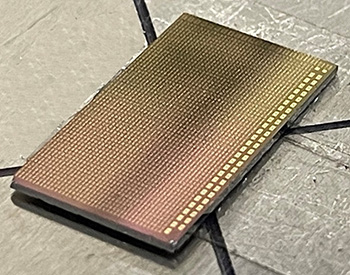

Khalili’s latest work attacks that problem. His team developed a new material structure for VCM, which has a significantly higher sensitivity of the magnetic properties to voltage, and therefore switches at smaller voltages than previous works. Importantly, this material structure simultaneously possesses all other important attributes for a practical memory device, including a high on/off ratio — also called tunnel magnetoresistance (TMR) ratio — and the ability to withstand high processing temperatures that are needed to make advanced semiconductor integrated circuits.

“Using this advanced material stack, we have now demonstrated, for the first time, VCM switching at less than one volt. We have also demonstrated the smallest VCM devices reported to date, which have a diameter of only 30 nanometers,” Khalili said.

These results remove one of the key barriers to the adoption of voltage-controlled MRAM by the semiconductor industry, and could enable a larger return on the investments that major semiconductor players have made in MRAM by widening the markets that MRAM can potentially address.

“The high sensitivity of magnetic properties to voltage in these devices may also impact other fields where magnetic nanodevices are currently used, in particular highly sensitive magnetic field sensors, microwave detectors, and energy harvesting devices in ultralow-power systems,” Khalili said.