Direct Solution Processing of Carbon Nanotubes in Solvent Cocktails

The findings lead to new ways to solution process carbon nanotubes without the usual need of dispersing agents or surface chemical treatment

Northwestern Engineering researchers have found new ways to directly solution process carbon nanotubes using just a cocktail of common solvents.

Carbon nanotubes, cylinders made of one or more layers of graphene, are very conductive and strong and can be used as a filler to make polymer plastic materials stronger. Processing them, however, is challenging, because they often come as powders of heavily aggregated nanotubes.

In earlier work, Northwestern Engineering’s Jiaxing Huang found that cresols – an inexpensive, mass-produced simple solvent once used in household cleaners – are very effective for dispersing nanotubes. What wasn’t known was why.

Using spectroscopic studies, Huang’s team has found the answer.

“Cresol forms a charge-transfer complex with carbon nanotubes,” said Huang, professor of materials science and engineering in Northwestern’s McCormick School of Engineering. “This interaction is stabilized in low-dielectric-constant solvents to keep the nanotubes dispersed, but it is destabilized in high-dielectric-constant solvents.

“This means that we now can formulate solvent cocktails that disperse carbon nanotubes, and others that can quickly wash cresols off the nanotubes. And the beauty is that no exotic new solvents are needed – these are all common industrial solvents,” he added.

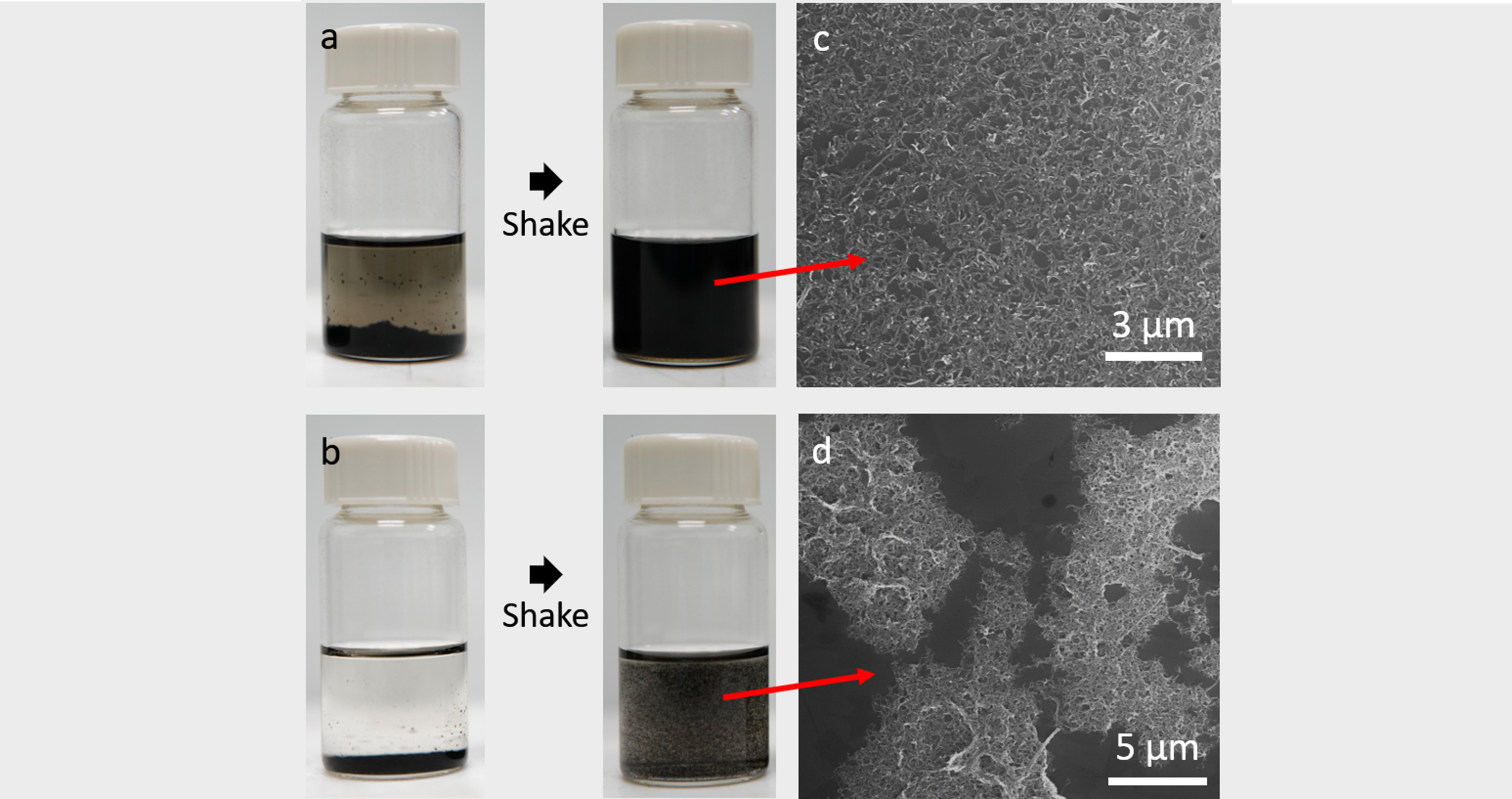

The study found that volatile compatible solvents, such as n-hexane and chloroform, can be used as the main solvent to formulate fast-evaporating nanotube inks for high-throughput techniques, such as airbrushing, to quickly create continuous and conformal carbon nanotube coatings. Next, incompatible solvents, such as acetone, can help remove residual high-boiling-point cresols without the usual need for heating.

“We now know mechanistically which cresol-‘flavored’ solvent cocktails are good to disperse nanotubes, and we know why,” Huang said. “And we also know what solvents can very easily remove residue cresols. It is a whole-circle technical solution for people thinking about solution processing of carbon nanotubes."

The study “Cresol-Carbon Nanotube Charge-Transfer Complex: Stability in Common Solvents and Implications for Solution Processing” was published July 1 in Matter. PhD student Kevin Chiou is co-author.

There have been numerous recipes to process carbon nanotubes. One previous method dispersed the carbon nanotubes through a chemical reaction to treat the surface with a layer of molecules.

The idea was to chemically graft a functional group (with a solvent-liking chemical structure) on the surface of nanotubes to make them more dispersible in solvents. That made the nanotubes more dispersible, but the process broke down the surface — important to the tube’s integrity.

Another approach required adding a molecule and dispersing agent. That method would theoretically wrap around the nanotube but not graft onto it. The problem with that, however, was that the process contaminates the nanotube material, and after processing, the agents still need removal.

This research builds on earlier work by Huang which discovered a way to disperse carbon nanotubes at unprecedentedly high concentrations without the need for additives or harsh chemical reactions to modify the nanotubes. In that work, Huang found that as the nanotubes’ concentrations increase, the material transitions from a dilute dispersion to a thick paste, then become a free-standing gel, and finally change to a kneadable dough that can be shaped and molded.