Measuring Flexibility: New Thickness-dependent Metric Compares Materials

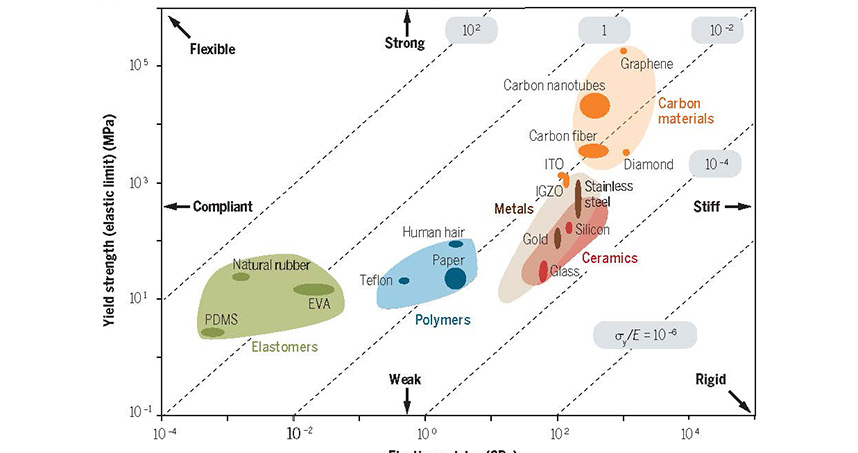

The figure of merit for flexibility considers thickness and compares yield strain of materials for flexible electronics

As fields ranging from health care to robotics increasingly use flexible materials for electronic devices, Northwestern Engineering researchers have developed a thickness-dependent metric that allows for the comparison of materials for device applications.

To make brittle electronic materials flexible, materials must be sufficiently thin — without making tradeoffs in performance. Utilizing yield strain — how much a material can stretch elastically before deforming plastically — can serve as a figure of merit (FOM) for flexibility comparing materials of the same thickness.

“Many materials scientists don’t use a rigorous definition and just show they can bend their materials," said G. Jeffrey Snyder, professor materials science and engineering in the McCormick School of Engineering.

“Many materials scientists don’t use a rigorous definition and just show they can bend their materials," said G. Jeffrey Snyder, professor materials science and engineering in the McCormick School of Engineering.

The research, “A Figure of Merit for Flexibility,” was published November 8 in Science. Snyder is a co-author of the paper with Jun Peng, a postdoctoral fellow in materials science and engineering and electrical and computer engineering. The paper emphasizes the scientific value of demonstrating flexibility while recognizing the importance of thickness in measuring the effectiveness of flexible materials.

Any material can be flexible if it is thin enough. For instance, glass is normally rigid and shatters if bent, but thin glass fibers are quite flexible, and optical glass fibers are used successfully for communications. Also, silicon microelectronics used for wearable and stretchable electronics are made of crystalline silicon, which becomes flexible when thin enough. Graphene and indium gallium zinc oxide can make flexible transparent conductors. Crystalline silicon is used in the flexible wireless sensors for premature babies which were developed by a Northwestern University team led by John Rogers, Louis Simpson and Kimberly Querrey Professor of Materials Science and Engineering, Biomedical Engineering, and Neurological Surgery.

Flexible materials can be stretched reversibly when they undergo elastic strain. The material property that characterizes the elastic limit is the yield strength, or maximum stress that a material can withstand before it breaks or deforms permanently.

Beyond thickness, flexibility of materials can be compared using the ratio of yield strength, which reflects how strong or weak a material is, to the elastic modulus, which measures how stiff the material is.

“Scientists who research new flexible materials should report and compare thickness and minimum radius of repeatable bending in order to show how flexible their new materials are,” Snyder said.

This research was supported by NASA-JPL Science Mission Directorate’s RPS-TE Technology Development program.