As COVID-19 infections escalated quickly into a global health crisis, Northwestern Engineering’s faculty and students applied whole-brain thinking to a host of challenges, ranging from moving classes online to proposing solutions to the health and logistics problems stemming from the pandemic.

Just hours after Northwestern announced it would move spring quarter courses online, McCormick School of Engineering faculty rallied to handle the unusual situation. In just over three weeks, faculty had closed out one quarter and begun a new, unprecedented one. They reimagined experiential courses as virtual. Seasoned online-teaching veterans shared tips for developing meaningful virtual courses that met Northwestern Engineering’s standards. Faculty provided mutual support with weekly meetups to maintain community.

With only certain essential research permitted to continue on campus, labs rapidly put physical distancing guidelines in place. Research groups moved their collaborations online. Faculty researchers, such as those in the Center for Synthetic Biology, began exploring ways to pivot their own research toward solving the global challenge.

Across Northwestern Engineering, one thing became clear: The time for engineers to lead had arrived. What follows shines a spotlight on only some of Northwestern Engineering’s major efforts as the pandemic took root and changed, perhaps forever, how we learn, live, and thrive.

Jump to a section to learn more:

COVID Diagnostics

Online Learning Adaptations

Hospital Supplies and PPE

Self-sanitizing Face Mask Project Receives NSF Rapid Grant

Northwestern Engineering’s Jiaxing Huang is developing a self-sanitizing medical face mask that deactivates viruses on contact, an initiative funded by the first Rapid Response Research (RAPID) grant awarded by the National Science Foundation for a physical sciences and engineering proposal. NSF called for immediate proposals that had potential to address the spread of COVID-19.

One way to slow or prevent the virus from spreading is to greatly reduce the number and activity of the viruses in just-released respiratory droplets, says Huang, professor of materials science and engineering, who led the research.

Huang’s team investigated anti-viral chemicals that can be safely built into masks to self-sanitize the passing respiratory droplets. Members of Huang’s laboratory, including graduate student Haiyue Huang and postdoctoral fellow Hun Park, worked to develop new solutions.

Traditional masks create a physical barrier that reduces the number of escaped respiratory droplets. The team aimed to design a drop-in solution that works generically with various types of existing masks to add the functionality of deactivating viruses. The new solution would help reduce the level of viruses in the droplets exhaled by infected wearers and better protect healthcare workers or others nearby.

“More researchers—and especially students in the physical sciences and engineering—should proactively study the problems and think of new ways to mitigate the transmission and spread of viruses,” Jiaxing Huang says.

- Amanda Morris

Helping Estimate States' Needs for Ventilators

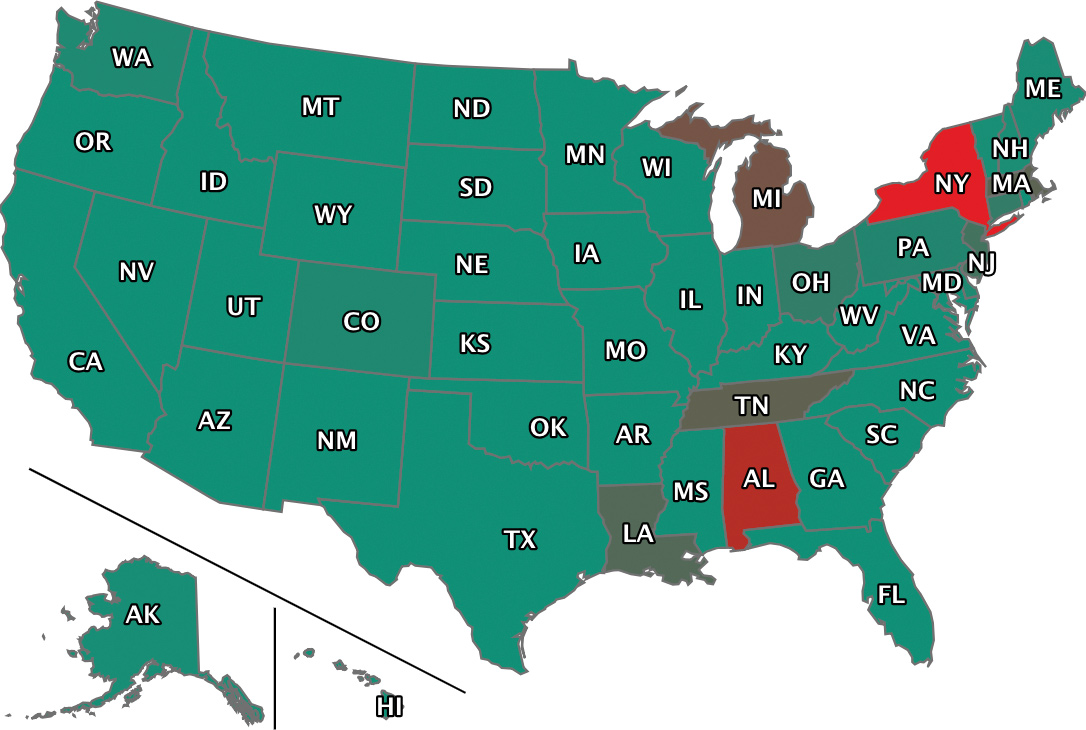

Motivated by New York’s need for ventilators as the state approached its COVID-19 pandemic peak, Northwestern Engineering’s Sanjay Mehrotra and collaborators developed a new model to help states allocate and share ventilators and other life-saving resources.

The computational model powers an interactive online procurement and distribution planning tool that acts as a central hub for information about each state. Preliminary results were released in April. Users can visit the site to see which resources, such as ventilators and hospital beds, states have or need. They also can explore the model’s recommendations for ventilator allocation and sharing from the national stockpile.

The model also provides estimates for when states will encounter different demand scenarios. Users can plug in different options—such as alternative scenarios, ventilator-sharing risk-aversion thresholds, and lead time—in order to find how many resources will be needed and what resources might be available under various conditions.

“It occurred to me that a model-based approach would allow us to systematically study and perform a ‘what-if’ analysis to support decision-making on this national issue,” says Mehrotra, professor of industrial engineering and management sciences.

The researchers’ goal is to discourage states from competing with each other for supplies, and instead to foster collaborative, strategic decision-making. The model uses data from the Institute for Health Metrics and Evaluation, estimates of historical ventilator inventory from CovidCareMap, initial ventilator inventory at the Federal Emergency Management Agency of the US Department of Homeland Security, and estimated ventilator production.

- Amanda Morris

Connecting Healthcare Providers to Vital Medical Resources

To move essential medical supplies to where they are needed most to combat the COVID-19 pandemic, Northwestern Engineering is collaborating with Chicago startup Rheaply to create Emergency Resource Exchange (ERx), a central supply hub.

Through ERx, healthcare providers can state their needs quickly, and suppliers across Illinois can respond with donated resources such as surplus equipment or newly manufactured goods. ERx data is sent to a continuously refreshed COVID-19 resource map, which offers real-time updates on the areas of greatest need to resource providers, journalists, government officials, and the public.

The collaboration was born out of a series of Idea Dialogues organized by Northwestern’s Roberta Buffett Institute for Global Affairs that included the McCormick School of Engineering’s Kris Hammond, Rheaply’s Garry Cooper, and staff from Northwestern Memorial Hospital. A Northwestern University Feinberg School of Medicine alumnus, Cooper is adjunct assistant professor of physiology at Feinberg and CEO and cofounder of Rheaply, a Chicago tech startup aimed at reusing and sharing resources through an exchange network. Hammond is Bill and Cathy Osborn Professor of Computer Science.

Key contacts at Northwestern Memorial consulted on common COVID-19-related resource needs and ERx platform design and helped to spread the word to local suppliers and healthcare facilities. “We hope that the platform and the COVID-19 resource map bring together interesting data that others can learn from in the future,” says Sarah Loehr, who acted as a project liaison via Northwestern Engineering.

- Erica Masini

COVID Diagnostics

Remotely Recognizing COVID-19 before Noticeable Symptoms Arise

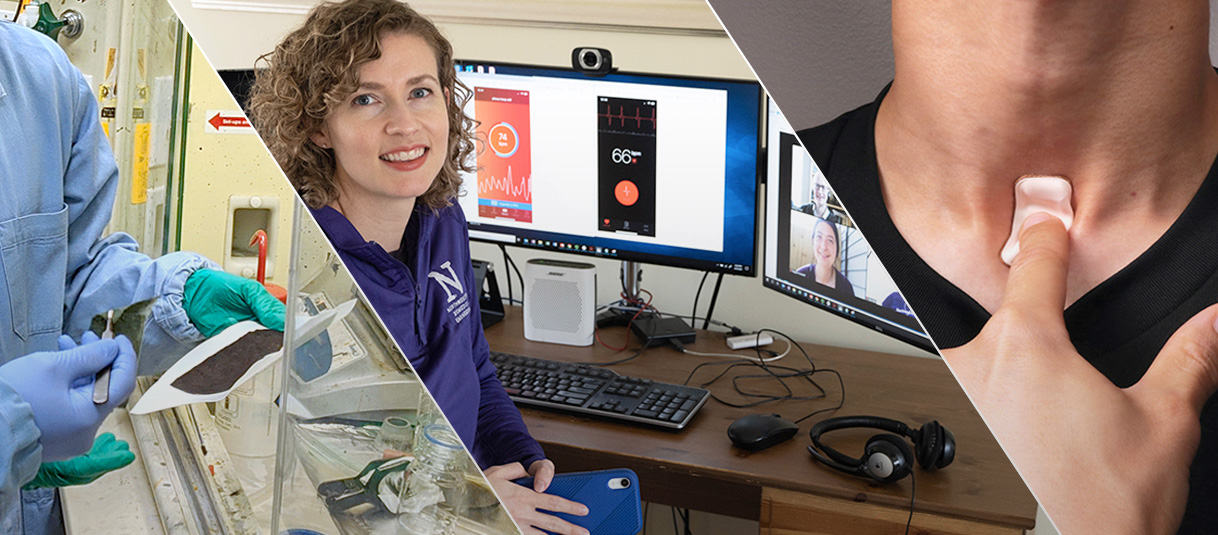

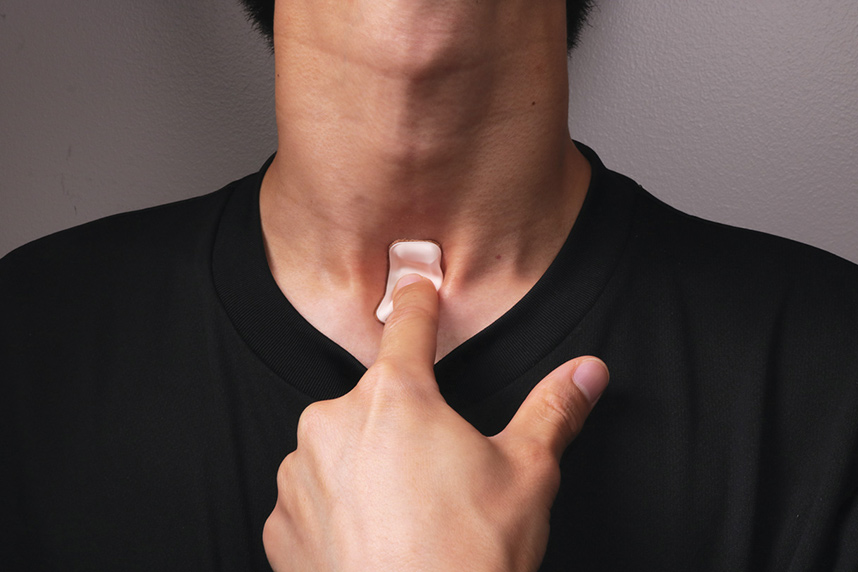

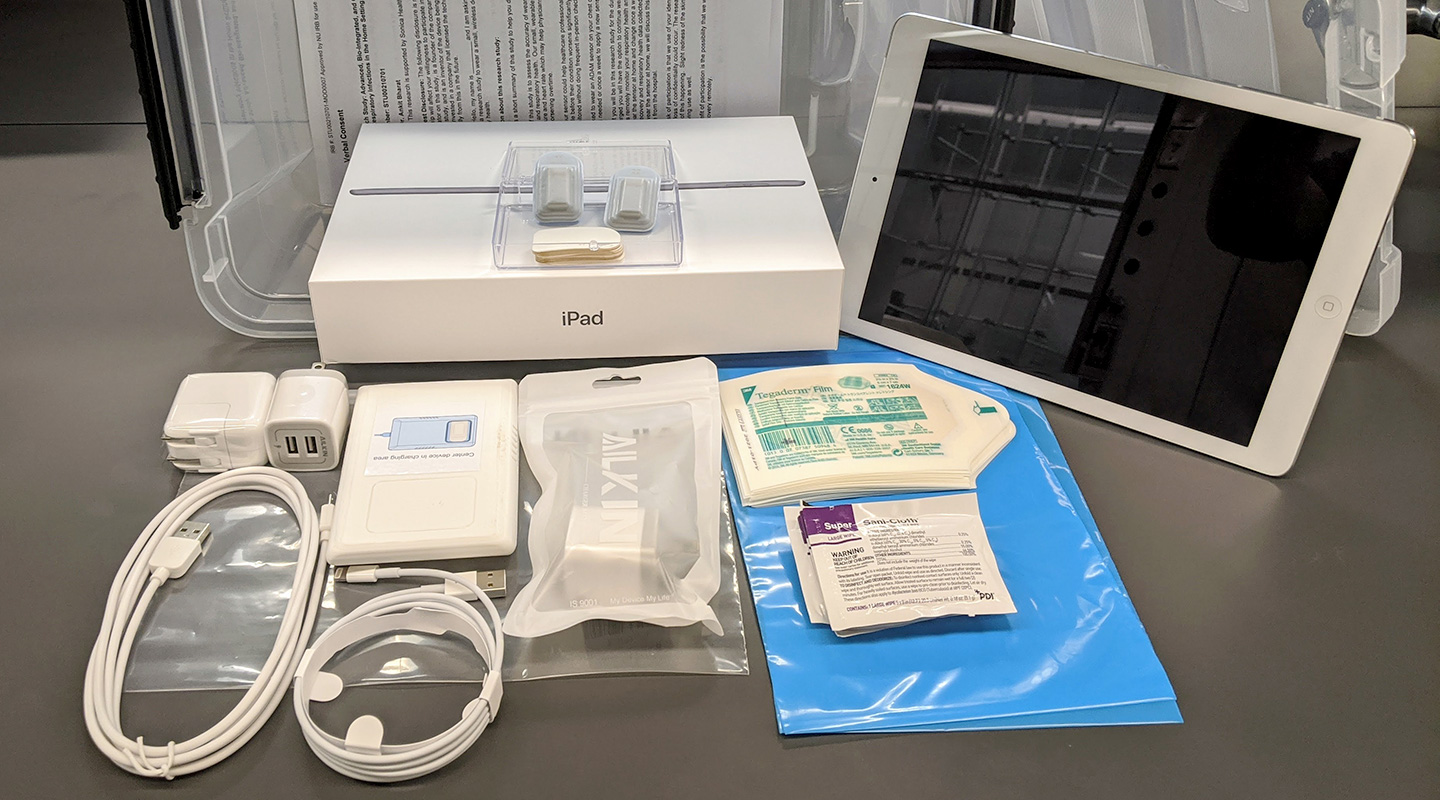

Researchers at Northwestern Engineering and Shirley Ryan AbilityLab in Chicago developed a novel wearable device and set of data algorithms specifically tailored to catch early signs and symptoms associated with COVID-19 and to monitor the progress of patients who contract the illness.

Worn 24/7, the device produces continuous streams of data and uses artificial intelligence to uncover subtle, but potentially lifesaving insights for COVID-19 patients and those exposed to the disease. Filling a vital data gap, it continuously measures and interprets coughing and respiratory activity, either at home or in the hospital, in ways not possible with traditional monitoring systems.

About the size of a postage stamp, the soft, flexible wireless device sits just below the suprasternal notch—the visible dip at the base of the throat. From there, the device monitors coughing intensity and patterns, chest wall movements (which indicate labored or irregular breathing), respiratory sounds, heart rate, and body temperature, including fever. From there, it wirelessly transmits data to a HIPAA-protected cloud, where automated algorithms produce graphical summaries tailored to facilitate rapid, remote monitoring.

Developed in a lab at the McCormick School of Engineering, the device first came into use in mid-April at the Shirley Ryan AbilityLab to monitor COVID-19 patients and the healthcare workers who treat them both in the clinic and at home with real-time data streaming. As of May 1, information from more than 1,500 cumulative hours had been collected, generating more than one terabyte of data.

Bioelectronics pioneer John Rogers, Louis Simpson and Kimberly Querrey Professor of Materials Science and Engineering, Biomedical Engineering, and Neurological Surgery, led the technological development.

The device could also provide early warning signals to frontline workers who are most at risk, offering the potential to identify symptoms before the workers notice them, allowing early precautionary methods and testing. Data from the device could also help researchers and physicians quantify which therapeutics work best.

“At the simplest level, our systems allow assessments based on data, in a quantitative way, without relying on human judgment of whether a patient is coughing more or less,” Rogers says.

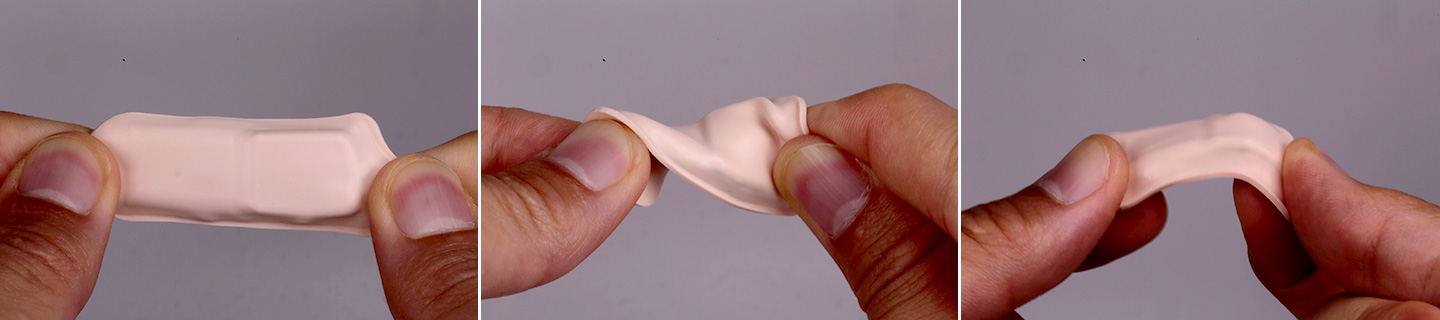

The new device builds on recent research focused on monitoring swallowing and speech disorders in patients recovering from stroke. These sensors precisely measure vibratory signatures from the throat and chest. Measuring vibrations rather than acoustics avoids noise from background sounds, and it bypasses privacy issues.

In response to requests and inquiries from the medical community, Rogers’s team realized they could use this technology to measure the vibratory signatures of COVID-like symptoms, including chest wall movements and cough. Because it is fully encased without wires, electrodes, charge ports, or removable batteries, the device can be worn continuously, for example while exercising or showering.

The design also permits sterilization and reuse. “This is absolutely critical for use in the context of this extremely contagious disease,” Rogers says. “Because it is fully sealed in a soft biocompatible silicone material, it can be completely immersed in alcohol and then exposed to a gas-based system for rigorous sterilization. If there were exposed regions, or plugs or ports or other physical interfaces, the device would not be relevant for this application.”

The team is examining data from patients recovering from COVID-19, and attempting to determine when they are no longer contagious.

- Amanda Morris

Engineering a Fast, One-Step Diagnostic Test

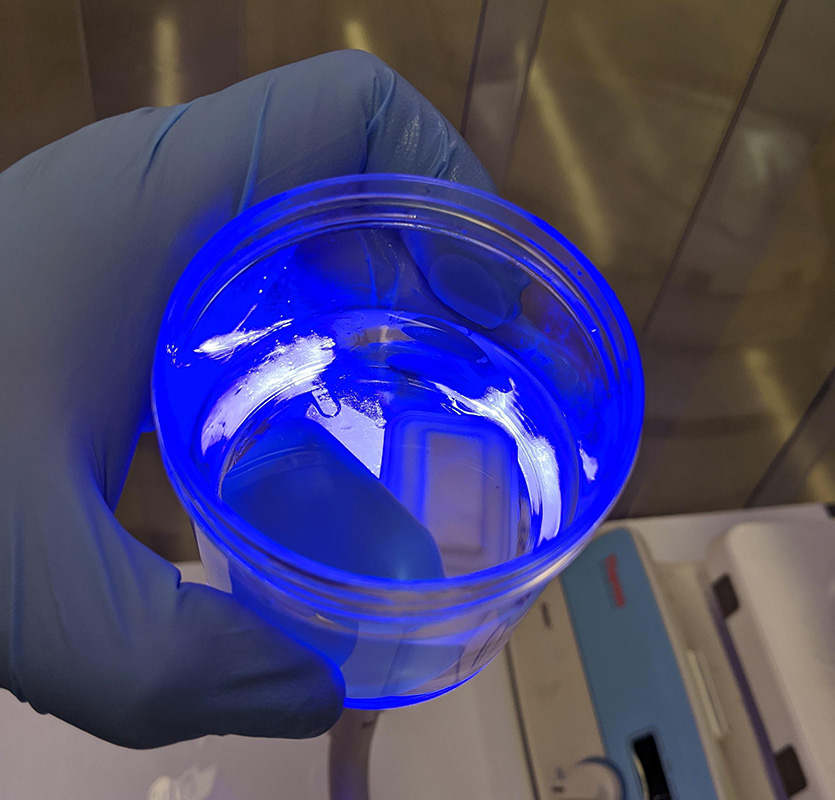

Northwestern Engineering synthetic biologists received funding to develop an easy-to-use, quick-screen technology that can test for infectious diseases, including COVID-19, either in the human body or within the environment.

Similar to a pregnancy test, the tool uses a single sample to provide an easy-to-read negative or positive result. By simplifying testing, the researchers could put diagnostics into the hands of people everywhere—eliminating the need for expensive laboratories or technical expertise. This could enable the large-scale testing required for ending stay-at-home orders, reopening the economy, or preparing for a predicted virus resurgence in the fall.

The team, led by Julius Lucks, is working to develop and optimize the test to provide a result in an hour and cost less than a dollar to manufacture. Lucks devised the project with fellow Northwestern Center for Synthetic Biology (CSB) members Michael Jewett, Joshua Leonard, and Niall Mangan. They partnered with Khalid Alam, a former postdoctoral fellow in Lucks’s laboratory and CEO of Stemloop Inc., which spun out of the CSB to commercialize rapid, field-deployable synthetic biology diagnostics technologies.

The test works by combining gene-editing tool CRISPR, custom genetic circuits, and cell-free synthetic biology to detect the virus and signal its presence. The team envisions that the final product could test patients’ samples from a nasal swab or saliva sample as well as from water and surfaces in the surrounding environment.

The project received a $200,000, one-year Rapid Response Research (RAPID) grant from the National Science Foundation.

- Amanda Morris

Online Learning Adaptations

Adapting the Lab Experience for Remote Learning

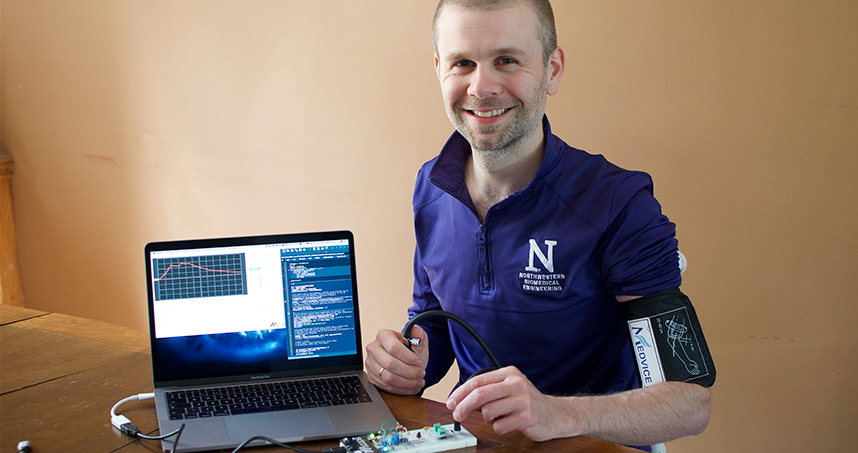

Separated physically from the teaching and research labs at Northwestern Engineering's Department of Biomedical Engineering, instructors who lead the experimental lab courses had to find creative ways to adapt their curricula to a remote learning environment.

“We quickly realized that none of our planned experiments would be possible,” says David O’Neill, Michael Jaharis Director of Experiential Learning and assistant professor of instruction in biomedical engineering. “We took a step back and thought, ‘What can we do that would allow us to conduct biomedical experiments?’”

In another lab, students studied how a smartphone’s camera light sensor, when paired with the free Physics Toolbox app, can measure distance. They used this understanding to test the accuracy of the sensor across different operating conditions, then applied that knowledge to study how common heart rate apps use a phone’s camera to measure heart rate.

“There is a tendency during lab courses for students to take on specialized roles,” says Matthew Tresch, professor of biomedical engineering and of physical medicine and rehabilitation, who cotaught the course with Casey Ankeny, assistant professor of instruction in biomedical engineering. “This format promotes distributed experimentation, where students learn each of the components while still emphasizing collaboration. ”Students recorded their own heart rates through a popular heart rate app and crafted experimental hypotheses based on the collected data.

- Alex Gerage

Adapting MaDE’s Capstone Course to the New Reality

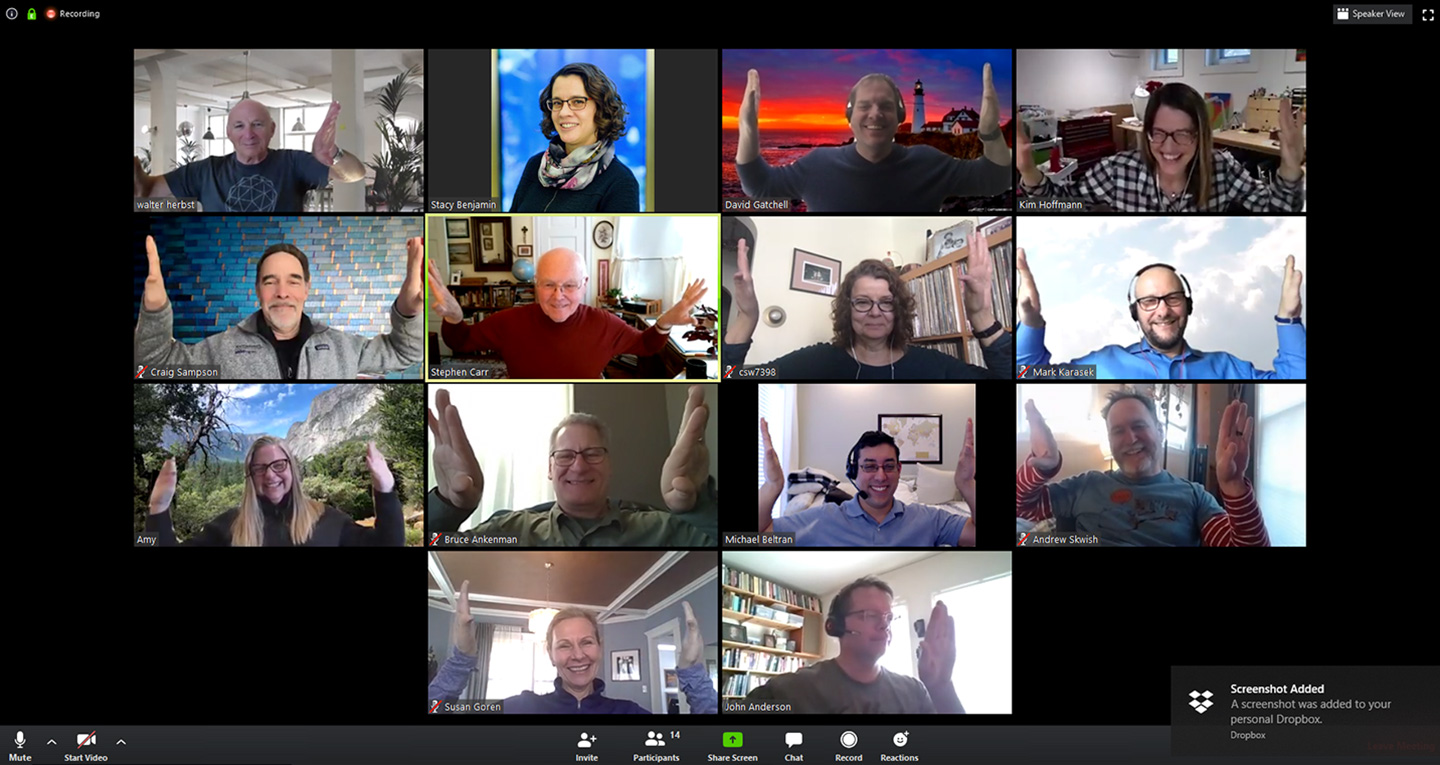

With deep concerns over the rising pandemic in mid-March, Clinical Professor Dan Brown and MaDE program director David Gatchell reimagined an online, yet hands-on experience for the Segal Design Institute’s capstone course, Manufacturing Engineering Design.

To maintain the rigor and learning outcomes of the typically shop-heavy course, the plan involved sourcing and assembling measurement tools and components to send to students around the world, enabling them to virtually manufacture fixtures for a bionic wrench assembly simulation in CAD for their final project.

For the remote version of the course, Brown immediately engaged the Segal Shop team to coordinate the challenge of getting tools to the students. Soon, approximately 40 kits were sent to students as far away as Hong Kong and Turkey.

Some staples of the course, such as twice-weekly lectures and professional mentoring, remain the same. There may be a hidden bonus: the students’ exposure to CAD and experience with virtual teamwork will enhance their abilities to work virtually with partners and clients all over the world in their professional careers.

- Brian Sandalow

Mastering the Moves to Take Studio Courses Online

Deploying an arsenal of new teaching tools, Segal Design Institute faculty banded together in a team effort to move studio courses for the Master of Science in Engineering Design Innovation program (EDI) online.

Jim Wicks, program director, and Amy O’Keefe, studio director, were tasked with preparing faculty to deliver two of the program’s required courses—Design Strategy and Thesis, and one elective, Mindful Product Management—in a virtual format.

O’Keefe and Kim Hoffmann, clinical assistant professor and EDI’s director of strategic initiatives, contacted the rest of the Segal faculty to understand the challenges of remote teaching.

Mike Edmonds, an adjunct professor who teaches Mindful Product Management, teamed with O’Keefe on a series of training sessions to introduce faculty to MURAL, a collaboration tool used by distributed design teams. Their goal was to help faculty feel comfortable using this new tool.

The EDI program also engaged dscout, a qualitative research platform, for two sponsored studios in Mindful Product Management and Design Strategy.

To prepare students thoroughly, Wicks used another innovative teaching tool— his family van—hitting the road to deliver class materials to students in nine Evanston locations. This enabled students not only to complete course work that required a physical component, but also to connect safely with mentor at a challenging moment.

“We want students to know that we’re working as hard as we can to build on the strengths of our community that will make this a good learning experience,” O’Keefe says.

- Brian Sandalow

Tackling Remote Learning as a Design Problem

To bring the Design Thinking and Communication (DTC) course to students remotely, class codirectors Alex Birdwell and Lisa Del Torto approached the transition as a design problem.

“We worked with more than 30 DTC faculty to brainstorm, design, and test new assignments and pedagogy, review work, and iterate as much as possible over the course of two weeks,” says Birdwell, associate professor of instruction at Northwestern Engineering.

Taught by faculty from the Segal Design Institute and Weinberg College of Arts and Sciences’ Cook Family Writing Program, DTC embeds communication instruction in the context of design, tasking first-year engineering students to work on design problems submitted by individuals, non-profits, and industry representatives.

Led by Birdwell and Del Torto, DTC faculty brainstormed a plan to adapt essential aspects of the second half of the two-quarter course for remote learning. Instructors emphasized virtual communication to develop and convey ideas among students and with clients. In-person meetings were replaced with phone calls, video chats, email, and shared documents. Hands-on design training in the Ford shop was replaced with an introduction to CAD.

Instead of physical prototypes for their projects, teams offered sketches, CAD models, storyboards, videos, and demonstrations for their final deliverable to clients, which included Shirley Ryan AbilityLab, Cygnus Lactation Services, and Trees that Feed Foundation.

“We trimmed DTC down to its essential elements,” Birdwell says. “Our evaluation of students focuses more on how they iterated their work while in their teams. These are positives, and we’ll look at ways to leverage these changes as we offer the course in the future.”

- Alex Gerage