New Center to Accelerate Biological Design for Sustainable Fuel and Bioproduct Production

Northwestern-led center receives $12 million grant from US Department of Energy

Northwestern Engineering will lead a new center dedicated to accelerating the production of sustainable, low-cost bio-fuels and chemicals. Called the Clostridia Foundry for Biosystems Design, the multi-institutional center has received a five-year, $12 million grant from the US Department of Energy.

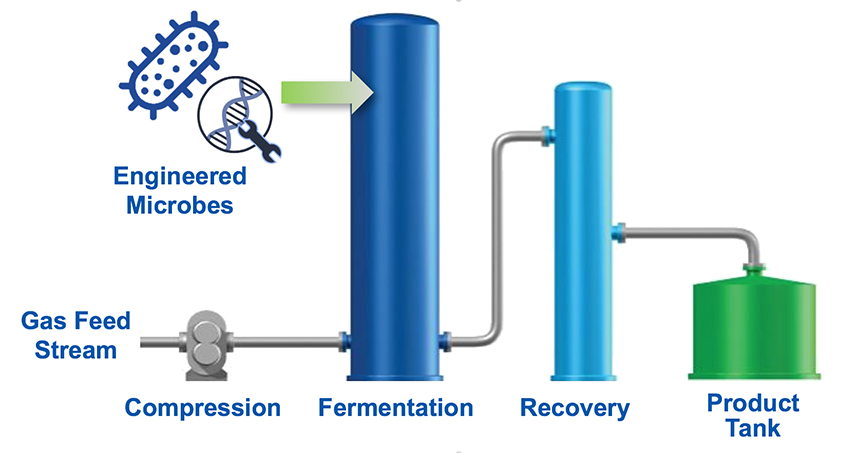

The center’s researchers — from Northwestern, Oak Ridge National Laboratory, and clean-energy startup LanzaTech — will focus on clostridia, a bacterium that metabolizes carbon to produce fuel.

“Clostridia can fix carbon from carbon dioxide and carbon monoxide and use it to grow and make something useful,” said Michael Jewett, the center’s principal investigator. “Essentially, it can turn waste into product.”

“Clostridia can fix carbon from carbon dioxide and carbon monoxide and use it to grow and make something useful,” said Michael Jewett, the center’s principal investigator. “Essentially, it can turn waste into product.”

Jewett is the Charles Deering McCormick Professor of Teaching Excellence and an associate professor of chemical and biological engineering in Northwestern’s McCormick School of Engineering. He also co-directs Northwestern’s Center for Synthetic Biology.

A waste-gas-to-fuel startup, LanzaTech houses a collection of clostridia strains. Michael Koepke, who leads LanzaTech’s synthetic biology team, is a leading expert in genomically manipulating clostridia. He and Jewett have been collaborating for the past two years to engineer clostridia to produce sustainable fuels, but engineering microorganisms to perform new tasks is not without its challenges.

“Microorganisms haven’t evolved to produce the sustainable chemicals that we want,” Jewett explained. “We end up fighting a tug of war between what the cell wants to do and what us engineers want it to do. It can take up to three months to test only a few designs for improving production, and that’s too slow.”

Jewett bypasses this problem by removing the cell from the equation. An expert in cell-free systems, he and his team isolate and activate basic cellular processes outside of the live, intact microorganism. This accelerates testing from a handful of designs in three months to thousands of designs in three days.

“If you have 1,000 shots on goal rather than just a few, then you have a much better chance at finding something that works,” Jewett said. “That’s pretty transformative.”

“This program will dramatically reduce the time required to develop new biosynthetic pathways in clostridia,” said Koepke, the director of synthetic biology at LanzaTech. “The effect will be to increase the flexibility of the LanzaTech process to adapt to new markets, expand the range of fossil-derived products that can be displaced with bio-derived alternatives, and enhance the economic benefits for co-produced fuels.”

Oak Ridge National Laboratory will lend its analytical tools and expertise to determine which of those 1,000 designs work the best at making bio-fuels and biochemicals. The resulting refined number can then be tested experimentally in Jewett’s laboratory and at LanzaTech.

Northwestern Engineering’s Linda Broadbelt, the Sarah Roland Professor of Chemical and Biological Engineering and associate dean for research, and Keith Tyo, associate professor of chemical and biological engineering, will complement Jewett’s experimental design techniques with computational approaches. Broadbelt and Tyo are co-principal investigators on the grant.

The center’s work will unfold in three phases. First, the team will identify the enzymes and computationally predict biosynthetic pathways within clostridia that are necessary to produce biofuels. Second, members of Jewett’s laboratory will work with LanzaTech to develop a technology platform for accelerating testing and pinpoint which iterations produce the highest yields. Finally, the team will demonstrate a Biosystems design approach to engineer clostridia for improved production of next-generation biofuels and bioproducts.

“There is a broad interest in using microorganisms to make fuels, so that we don’t have to source them from petroleum, which we know is a limited resource,” Jewett said. “What’s especially cool is that we can use biology to make sustainable products while removing carbon from the atmosphere at the same time. It’s a really green solution with the potential to become a major driver of global innovation and sustainable economic growth.”