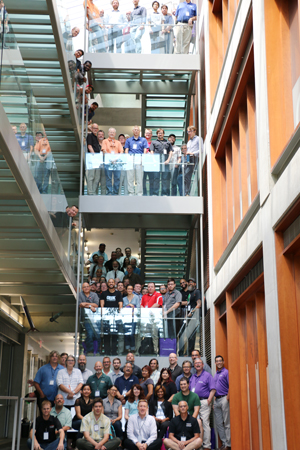

University Shop Managers Gather at Northwestern to Discuss Safety

More than 85 educational shop managers and staff from universities around the country met on campus for the three-day conference

Students interested in using the mills, drill presses, and laser cutters in Northwestern’s Prototyping and Fabrication Lab may soon “sign in” with the press of a finger.

To add additional accountability and safe access to the University’s shop equipment, members of Northwestern’s Segal Design Institute have developed a prototype biometric device that uses fingerprint authentication to monitor machine usage. The system, which was designed to easily integrate into existing shop machines like lathes, mills, and lasers, utilizes a fingerprint scanner and camera to identify a trained user before allowing access to the equipment. Data from the fingerprint can then be cross-referenced in a database maintained by the shop’s staff that houses information related to that user’s training experience.

If the system shows that the user has received proper training, a light affixed to the machine will turn green. If the student has not undergone appropriate training protocols, the light will turn red, and a notification will be sent to shop staff or nearby university police after hours, who can check on the situation and prevent unauthorized equipment usage.

The prototype device was presented at the third Student Shop Managers Conference (SSMC), which took place July 11-13 in the Ford Motor Company Engineering Design Center. Hosted by Northwestern’s Segal Design Institute, the conference welcomed more than 85 shop managers, technicians, faculty, and staff from schools across the nation, including Stanford, MIT, Georgia Tech, Harvard's Graduate School of Design, and Yale.

Guided by the theme “Student Safety, Training Standards in Educational Shops,” SSMC focused on fostering industry benchmarked standards and practices to improve the training, safety, and operations areas of educational shops. Leveraging their backgrounds in engineering, design, art, architecture, research, and theatre, attendees worked together during interactive seminars and small group discussions to address how to combine theory and practice in education through proficiency in safe and sustainable training environments.

Guided by the theme “Student Safety, Training Standards in Educational Shops,” SSMC focused on fostering industry benchmarked standards and practices to improve the training, safety, and operations areas of educational shops. Leveraging their backgrounds in engineering, design, art, architecture, research, and theatre, attendees worked together during interactive seminars and small group discussions to address how to combine theory and practice in education through proficiency in safe and sustainable training environments.

“Safety should be open-sourced, not one school’s competitive advantage,” said Dan Brown, clinical associate professor at the Segal Design Institute and SSMC 2017 conference chair. “By coming together and exploring new ideas, we can move closer to finding solutions that benefit all of our operations and make our students safer.”

In addition to presentations and networking opportunities, the conference included tours of several Northwestern maker facilities, including the Ford Prototyping and Fabrication Lab, Vehicle Team Spaces, the 3D Printing and Rapid Prototyping Lab, Research Shop, The Garage, and the School of Communication’s stage design shop.

Stemming from the conference’s emphasis on training standards, a panel discussion tackled how to bridge the gap between theory-based and practice-based learning. Experts shared ideas on how to promote maker culture within traditional curriculum, from developing a certificate program around practice-based proficiencies to offering more seminars and learning opportunities that highlight the importance of hands-on design projects.

“When theory does not match practice, it creates a professional disconnect,” Brown said. “Students will lack practical insights, and their overall education experience suffers. Students need to learn how to practice safely, and it will to take people like us leading outreach efforts to build that trust and respect with key stakeholders.”

Amy Kavalewitz, executive director of the Oshman Engineering Design Kitchen at Rice University, added that students can also serve as champions of maker culture.

“Students are entering our programs having already undergone training with 3D printers and lasers in high school,” Kavalewitz said. “They are now expecting active learning opportunities. This shift will continue to establish our facilities as a vital part of education.”