Developing Medical Devices for the Developing World

McCormick students study and work to improve healthcare in Cape Town

A “rainbow nation” of races and cultures. Eleven official languages. A potent mix of developed and developing worlds. South Africa is a country of contradictions. Nowhere is that more evident than in Cape Town, where cosmopolitan shopping malls and luxury beach homes stand in startling contrast to the makeshift shantytowns just a stone’s throw away.

For the 16 Northwestern students who traveled to Cape Town this spring as part of McCormick’s Global Health Technologies study abroad program, those contradictions are exactly what drew them there. For 10 weeks, in conjunction with their studies at the University of Cape Town, they visited community healthcare clinics, interviewed healthcare workers, and created devices and processes to help improve healthcare delivery.

Of course, they knew they weren’t going to solve the region’s problems in 10 short weeks. They did, however, gain a valuable first-person perspective of what it means to design for a new culture, where, for example, patients don’t have the same notion of making appointments, or where electrical power frequently goes out.

DESIGNING FOR A NEW CULTURE

“Our students in this program get a true sense of design,” says Matthew Glucksberg, the professor of biomedical engineering who heads the program through McCormick’s Center for Innovation in Global Health Technologies. “They can’t just fall back on what they know. They must take their engineering skills and seek solutions that could actually work in resource-limited settings.”

By living and working together in a house near campus (where the posted house rules range from “wash pans after using” to “assume best intentions”), students could spend much of their time iterating designs, getting feedback from their professors and from users, and then working together to start the process all over again.

At the end of the quarter, the group had four prototypes: a simple carbon dioxide detector to help paramedics intubate patients, a tablet app to help clinic nurses diagnose diseases and prescribe treatments, a new kind of mask for protecting against tuber- culosis, and an app for a clinic kiosk that would help patients book appointments.

Such projects require years of work before they are ready for clinic implementation, but the lessons the students learned can be applied as they graduate and move on to their careers.

“It’s not just us coming in and saying, ‘We’re going to help save you,’” says student Petrina LaFaire (biomedical engineering ’15). “It’s very much a learning process for us, and that has been great. I’ve learned that failure is okay. Iterating an idea is not only acceptable, it’s necessary.”

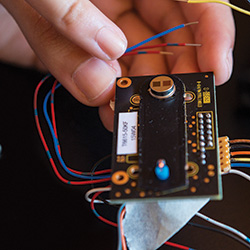

ETCO2 INDICATOR

Problem: Breathing difficulties.

When paramedics intubate patients with breathing tubes, they often have difficulty determining whether they’ve inserted the tube down the trachea, which leads to the lungs, or down the esophagus, which leads to the stomach. Esophageal intubation can lead to death.

Solution: A carbon dioxide sensor.

The team originally focused on creating a capnograph, which creates a graph of carbon dioxide coming from the lungs over time, but concluded that would be too expensive and more complicated than necessary. “We realized the best way to cut costs is to cut out some functionality,” says team member Hannah Baiyor (biomedical engineering ’15). “Instead of a graph, we created a sensor that can determine whether or not air is coming from the lungs. It’s an LED light that says ‘yes’ or ‘no.’ We learned that high tech doesn’t necessarily mean better. Sometimes, a simpler design is actually the best.”

Challenges: Material procurement.

The project required optical equipment, which had to be ordered from the United States. “We had issues with customs,” says team member Eric Yang (biomedical engineering ’15). “We had to email for several weeks to figure out how we would get these components in our hands.”

Lessons Learned: Designing for the developing world.

“You can’t just build something and expect it be universally acceptable,” Baiyor says. Students found, for example, that many medical devices that are considered disposable in the United States are used several times in the clinics. “You also can’t just donate old medical devices to the developing world,” Yang says. “It’s not as simple as saying, ‘We don’t want this anymore, maybe they can use it.’ If it doesn’t work for us, it’s not going to work for them.”

IMCI+ TABLET APPLICATION

Problem: Diagnosing the right disease.

When confronted with common ailments like fevers, diarrhea, and ear problems, clinic nurses often turn to Integrated Management of Childhood Illness (IMCI), a handbook created by the World Health Organization and UNICEF that helps them assess and treat childhood illnesses in resource-poor environments. Five years ago, McCormick students in the study abroad program created an Android tablet app to make the guide digital. Feedback showed that nurses actually took longer to find a diagnosis using the app than the handbook. “We wanted to streamline the process and make it more accurate and thorough,” says team member Nick Brandis (civil engineering ’15). “We wanted nurses to see it as useful enough to warrant the time it would take.”

Solution: A new version of the app.

The team expanded the app by adding modules that allow nurses to see a patient’s history, prescribe treatments, access counseling material, and book another appointment. “It adds time, but these steps are all part of the consultation anyway, so it saves paperwork,” says team member Tessa Swanson (industrial engineering ’16).

Challenges: Limited timeframe.

The team submitted a request to conduct user testing, but approval wasn’t communicated back to them for several weeks. That meant they had to scramble to conduct user testing in their final weeks.

Lessons Learned: Project management.

“With such a short timeframe, you really need to break down your priorities and establish your methods for reaching your goals,” says team member Kera Scheffel (biomedical engineering ’15). “You need to recognize early on what resources are available.”

TUBERCULOSIS PERSONAL PROTECTOR

Problem: Uncomfortable protective masks.

In South Africa, where tuberculosis affects about 500,000 residents a year, protecting healthcare workers from contracting the disease is extremely important. But current paper masks that cover the nose and mouth are unpopular among clinic staff. “The masks are uncomfortable, and they make it hard to breathe,” says team member Danielle Marks (biomedical engineering ’15). “They cause rashes and irritate the skin, so many workers don’t wear them at all.”

Solution: A redesigned mask.

The team developed a new mask that incorporates a plastic face shield and an airflow system that blows purified air toward the healthcare worker’s face. The sys- tem uses an ultraviolet germicidal irradiation lamp worn in a backpack that draws in potentially infected air, treats it, and directs it through a tube toward the worker’s mouth. A plastic face shield attached to the pack and positioned a few inches away from the face protects the worker from patients’ coughs and sneezes without irritating the skin.

Challenges: Access to machinery and materials.

Although the University of Cape Town has a machine shop, students have only limited access to the machinery. The students also found that securing parts for the protector was more challenging than making a quick trip to a nearby big box store. “The materials we needed had to be sourced from small local shops,” says team member Mike Aleman (mechanical engineering ’15).

Lessons Learned: Coping with conflicting opinions.

“When we interviewed nurses, some said they wanted a mask one way, but then others said they didn’t want it like that at all,” says team member Regan Via (biomedical engineering ’15). “It highlights the importance of learning exactly what your clients really need, and figuring out what that means for a client who has a perspective very different from yours.”

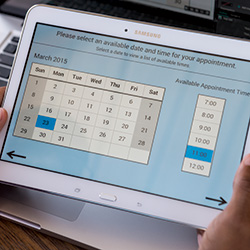

APPOINTMENT BOOKING PORTAL

Problem: Missed appointments.

Because South Africa provides its citizens free access to healthcare, community health clinics often deal with long waiting lines, and patients must often accept appointments at times they cannot visit the clinic. The problem varies from clinic to clinic: at some, patients show up early in the morning, whether they have an appointment at that time or not, because they think they will be seen faster. At others, patients routinely miss appointments that are booked later in the day. At one of the clinics the students visited, none of the 20 patients booked for an 11 a.m. appointment showed up.

Solution: A booking app and kiosk.

Students worked to create a tablet app that would guide patients through the steps of booking their next appointment at the time and date of their choice. That way, the patient would have more ownership of the appointment and perhaps would be more likely to show up. The tablet would be housed in a kiosk at the clinic for safekeeping.

Challenges: Technical literacy.

Many of the people who visit the community health clinics are unfamiliar with touchscreens and common user interface conventions. After gathering user feedback, students changed the wording of the app’s instructions to clarify how to use it.

Lessons Learned: Looking beyond the presented problem.

Though healthcare workers asked for a booking portal, the team wondered if that would actually help alleviate the problem. “Would it be better if the healthcare workers booked future appointments at the end of their current appointment?” says Anna Rietti (biomedical engineering ’15). “We’re trying to figure out the real problem, not just go with the most obvious solution.”