ResearchStructural Reliability and Nondestructive Characterization

Ultrasonic Materials Characterization

The ultrasonic materials characterization research area is focused on the development of advanced ultrasound-based experimental techniques for the characterization of material properties, the study of elastic and inelastic behavior of materials, failure analysis and prediction, and nondestructive evaluation. Research activities include modeling of ultrasonic waves in porous and non-porous solids across multiple scales, photoacoustic and piezoelectric generation of ultrasound, local and full-field detection of ultrasound, and optical metrology.

The applications of the focus areas range from the prediction of functional reliability of materials, process monitoring, defect metrology in semiconductor materials, material damage diagnosis, and understanding microstructure-property relationships.

Research Areas

- Photoacoustic characterization of nanoscale structures

- Photoacoustic microscopy for defect metrology applications

- Ultrasonic characterization of the microstructure of cement-based materials

- Full-field ultrasonic imaging for nondestructive evaluation applications

- Characterization of fatigue damage using nonlinear ultrasound

Structural Health Management

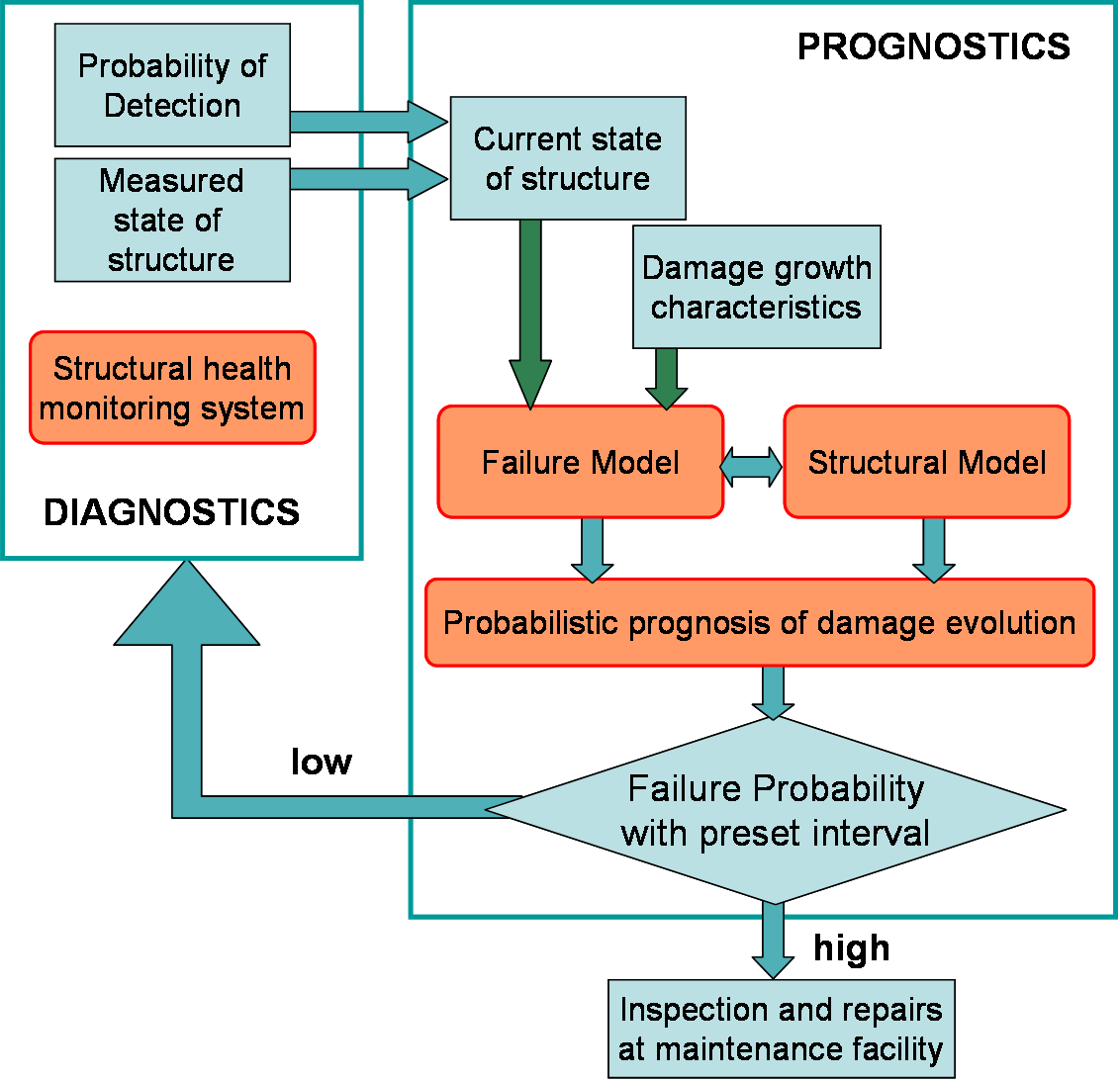

The Structural Health Management (SHM) research area is focused on the development of an integrated approach to intelligent structural health management (ISHM) of safety-critical aerospace, mechanical and civil structures. Intelligent SHM involves feedback-based prediction of structural integrity. On-board diagnostic sensors provide continuous or on-demand information about the state of a structure, and the data from the sensors is incorporated into structural analyses and damage evolution models to assess the state of the structure, and to make probabilistic prognoses about the remaining lifetime. Intelligent SHM represents a shift away from routine inspections which are currently scheduled based on ensemble statistics, to inspections that are scheduled based on the actual state of the structural health of individual structures. This approach results in improved safety as well as in increased efficiencies in terms of cost and downtime.

Research Areas

- Development of diagnostic fiber optic sensor arrays for dynamic strain monitoring

- Development modally-selective piezoelectric Lamb wave sensors

- Fatigue damage prognosis