Research / Micro/NanomechanicsNanomechanical Testing of Nanowires and Nanotubes

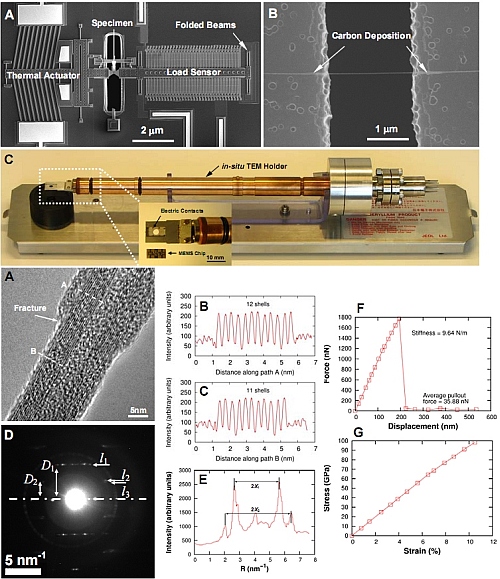

Nanomechanical testing of nanostructures like MWCNTs, nanowires, and thin films, is quite challenging. At Northwestern Engineering we have developed the first nanomaterial testing systems (N-MTS) capable of the simultaneous measurement of force-displacement signatures and acquisition of high resolution atomic images. The system is based on MEMS technology and can fit in tiny volumes, as required by in-situ transmission electron microscopy (TEM) testing. Using this novel testing platform we have correlated force measurements to the failure of a single shell in a multiwalled carbon nanotube. Electron diffraction induced by the carbon atoms is used to determine the CNT diameter and chiral numbers.

The advanced mechanics group works to characterize and model the complex behaviors SMAs exhibit at different scales, spanning the range of molecular interactions, micromechanical phenomena, and macroscopic responses. One of the primary areas of focus is to better understand the evolution of the alloys microstructures as they undergo phase transformations. To achieve this, a vast repertoire of experimental techniques is utilized including neutron diffraction measurements, optical microscopy with digital image correlation measurements, and electron microscopy, all with in situ thermo-mechanical loading of specimens. The findings are captured in the formulations of models that traverse the realms of nanomechanics, micromechanics, continuum mechanics, thermodynamics, molecular dynamics, and kinetics. The ability to successfully apply these models to complicated loading scenarios as well as advanced devices, such as porous SMA structures and self-healing composites, is essential and utilized in projects such as developing microarchitectures optimized for bone implants.

The figure below shows displacement and strain measurements made using digital image correlation techniques during the phase transformation of a NiTi alloy.